Protein hydrolysates present cost-effective approach for their inclusion in animal feed with the aim of improving health status and productive parameters.

Improving feed use efficiency for milk, meat and egg production, is one of the main goals of animal production(Wu et al. , 2014). This approach requires optimal nutrition to support the small intestine’s function as the target site for nutrient digestion and absorption.

Peptides obtained from the hydrolysis of plant and animal proteins are included in pig, poultry, fish and pet diets. This type of dietary inclusion presents positive and cost-effective results, that contribute to gut health improvement, and increased growth and productive performance(McCalla et al., 2010).

Proteins, peptides y aminoacids

Proteins are macromolecules which are usually made up of of twenty different amino acids (AA) linked by peptide bonds. They are a major component of animal tissues (skeletal muscle, mammary glands, liver, etc.) and products such as meat, milk, egg, and wool.

The protein content found in the skeletal muscle of growing cattle or pigs is about 70% based on dry matter (Wu et al., 2016).

Therefore, adequate dietary protein intake is essential to obtain maximum growth, productive yield and feed efficiency in livestock, poultry and fish.

After being consumed by animals, proteins found in feed ingredients (e.g., blood meal, meat and bone meal, fish meal, soybean meal, peanut meal, and cottonseed meal) become hydrolyzed into small peptides and free AA by proteases and oligopeptidases within the small intestine.

Amino Acids are organic substances that contain amino and acid groups. All AAs have a α-amino group and occur as L-isomers in animals and food. Being glycine the only exception to the latter.

A peptide is defined as an organic molecule consisting of two or more AA residues linked by peptide bonds.

Generally speaking, polypeptides with a molecular weight of ≥ 8000 Daltons (i.e. ≥ 72 AA residues) are called proteins. However, the distinction between proteins and peptides on the basis of their molecular weights is not absolute.

- For example, insulin (51 AA residues) is recognized as a protein because it has a defined three-dimensional structure which is a characteristic exhibited by proteins.

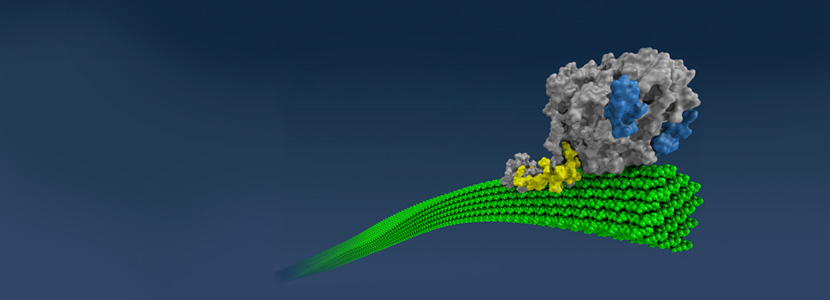

Proteins are arranged in four structures (Figure 1):

- Primary structure: the sequence of AA along the polypeptide chain;

- Secondary structure: the conformation of the polypeptide skeleton;

- Tertiary structure: three-dimensional arrangement of proteins;

- Quaternary structure: the spatial arrangement of polypeptide subunits.

The primary sequence of AA in a protein determines its secondary, tertiary and quaternary structures, as well as its biological functions.

Figure 1. Protein structures

Production of protein hydrolysates

To consistently manufacture peptides from animal and plant protein sources, chemical, enzymatic or microbial methods have been employed in order to improve their nutritional quality and reduce any associated anti-nutritional factors prior to their inclusion within animal feed.

The latter two methods can also improve peptide solubility, viscosity, gelling capacity and emulsification. [register]

The method of choice for protein hydrolysis depends on its source:

- Proteins obtained from feathers, bristles, horns, beaks or wool contain a keratin structure. Therefore, these are usually hydrolyzed with the use of an acid/alkaline treatment or by bacterial keratinases.

- In contrast, animal products (e.g., casein, whey, intestines, and meat) as well as plant ingredients (e.g., soybeans, wheat, rice, peas, and cottonseed proteins) are often subject to enzymatic or microbial hydrolysis.

After hydrolysis, insoluble fractions are separated from the protein hydrolysates with the use of a centrifuge, filter or microfiltration system. The obtained protein hydrolysate is then heat-treated (pasteurized) to kill or reduce the number microorganisms. The product is then dried and packaged.

Protein hydrolysates include:

- Free AA

- Small peptides

- Large peptides

Acid hydrolysis of proteins

Most acidic protein hydrolysates are used as flavor enhancers. One of the advantages of this type of hydrolyzation method, is its low cost.

- However, this process results in the complete destruction of tryptophan, a partial loss of methionine and the conversion of glutamine to glutamate and asparagine to aspartate (Pasupuleki et al. , 2010).

Alkaline protein hydrolysis

Alkaline agents, such as calcium, sodium or potassium hydroxide, can be used at high temperatures(e.g. 105 °C) to obtain a complete protein hydrolysis during a 20 h period.

Like acid hydrolysis, alkaline hydrolysis offers the advantage of a low cost and can present a tryptophan recovery rate of 100%.

- However, this process results in the complete destruction of most AAs.

Cell-free proteases

The peptide bonds of proteins can be broken down by many different types of proteases, which can be classified as exopeptidases and endopeptidases according to the type of peptide bond hydrolysis:

- In the terminal region: exopeptidase

- Within an internal region: endopeptidase

Enzymatic hydrolysis takes place under mild conditions (e.g. pH 6–8 and 30 – 60 °C) and minimizes side reactions. Most enzymes are obtained from animal, plant, and microbial sources. The choice of enzymes depends on the source of protein and the degree of hydrolysis.

The advantages of enzymatic hydrolysis of proteins are:

- a) Hydrolysis conditions (e.g. such as temperature and pH) are mild and do not result in any loss of AA;

- b) Proteases are more specific and precise in controlling the degree of hydrolysis of the peptide bond;

- c) Small amounts of enzymes can be easily deactivated after hydrolysis (e.g. 85 °C for 3 min) to facilitate the isolation of protein hydrolysates.

The disadvantages of enzymatic protein hydrolysis include the relatively high cost and the possible presence of enzyme inhibitors in protein raw materials.

Microbial hydrolysis of proteins

Microorganisms release proteases to hydrolyze extracellular proteins into large peptides, small peptides, and free AA.

The main advantages of fermentation are that properly used microorganisms can not only break down proteins into free peptides and AA, but can also eliminate antigenic or anti-nutritional factors present in the ingredient matrix(e.g., trypsin, glycinin, raffinose and stachyose inhibitors).

The disadvantages of microbial hydrolysis of proteins are its relatively high costs, as well the changes in microbial activity under different conditions. Which results in an inconsistent production of free peptides and AA.

Bioactive peptides in protein hydrolysates

Bioactive peptides are fragments of AA sequences within a protein that confer it biological functions beyond its nutritional value (López-Barrios et al., 2014). They usually have a length of 2 to 20 AA residues.

These possess some of the following properties or activities:

- Antimicrobial

- Antioxidant

- Antihypertensive

- Immunomodulatory

Peptides antioxidants and antimicrobials

Many small peptides from animal products (e.g., fish and meat) and plant-based foods have antioxidant functions such as: scavenging free radicals and/or inhibiting the production of oxidants and pro-inflammatory cytokines.

These small peptides can reduce the production of oxidants in the small intestine, while improving the elimination of oxidants. Reducing their intracellular concentrations and relieving oxidative stress.

In swine nutrition, most studies related to dietary peptide inclusion have been conducted with piglets after weaning to improve palatability, growth, health, and feed efficiency (Lindemann et al., 2000; Stein, 2002).

- This is mainly due to the fact that young animals have immature immune and digestive systems. Therefore, weaned piglets tend to suffer from reduced feed intake, intestinal atrophy, diarrhea and subsequent growth problems.

Peptide products have also been used to supplement calve diets (Lalles, 1995), poultry (Opheim, 2016), fish (Khosravi, 2015) and companion animals (Nagodawithana et al., 2010) with the purpose of improving their nutritional status, intestinal function and ability to withstand infectious diseases.

Conclusion

Plant and animal protein hydrolysates provide highly digestible peptides and bioactive peptides. As well as providing specific AAs which confer nutritional, physiological and regulatory functions in animals.

The industrial production of these protein hydrolysates involves: strong acidic or alkaline conditions, enzymatic methods and/or microbial fermentation.

- Chemical hydrolysis is often employed to generate tasty flavors, while microbial fermentation not only produces peptides, but also removes anti-nutritional factors from protein ingredients.

In addition to their nutritional value, bioactive peptides have antimicrobial, antioxidant, antihypertensive and immunomodulatory functions. These peptides exert beneficial effects to improve intestinal morphology, function and infectious disease resistance in animals.

| This provides a cost-effective approach for converting high-quality protein hydrolyzed animal by-products, brewery by-products or plant foods, into feed for livestock, poultry, fish and companion animals. |

Source: Hou et al., 2017

[/register]