Properly processed full-fat soybean (FFSB) stands out for its wide use in all types of feed. Its high oil and protein contents, together with the quality of its fractions and high palatability, make it especially beneficial in early age feeding.

In addition to its high value in energy and amino acids (AA), FFSB provides significant amounts of phospholipids, substances rich in linoleic acid, phosphorus, vitamin E and choline (Paulding et al., 1986; Ravindran et al., 2014a; CVB , 2019; FEDNA, 2019).

It should be taken into account that the nutritional value of processed soybeans, although more uniform than most raw materials, varies depending on factors such as the type of seed, origin of the bean, the environmental and agronomic conditions of the sowing area during growth, harvest time, storage & thermal processing conditions of broad bean (Piper and Boote, 1999; Grieshop et al., 2003; Karr-Lilienthal et al., 2004; Goldflus et al., 2006; Lee et al., 2013; Zhang et al., 2019).

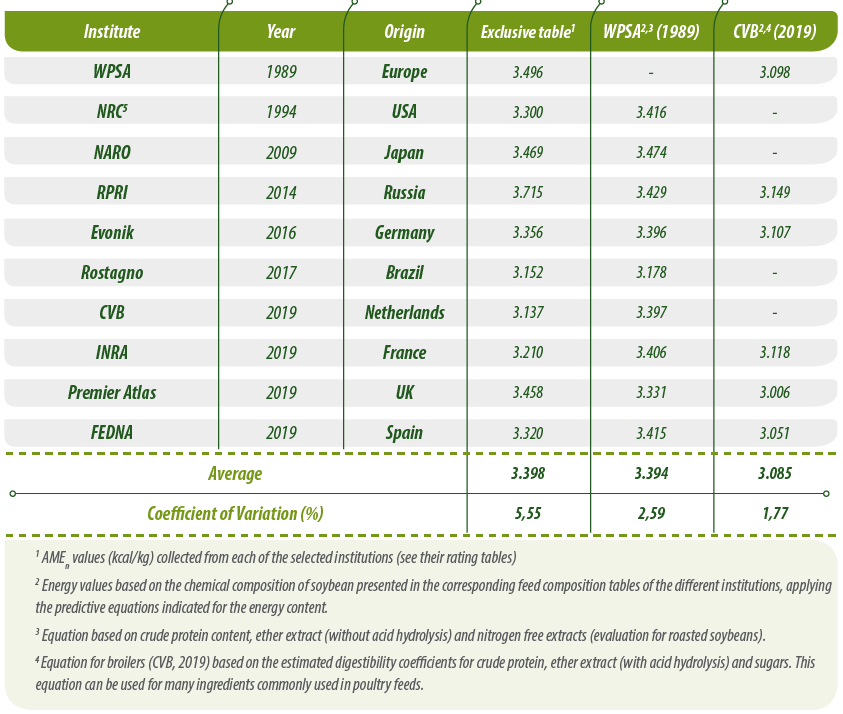

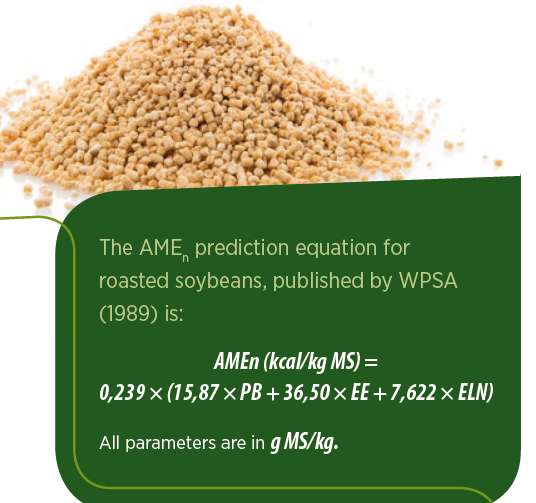

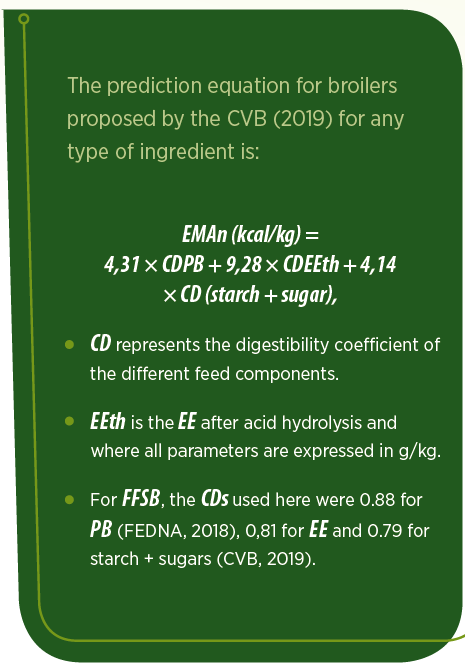

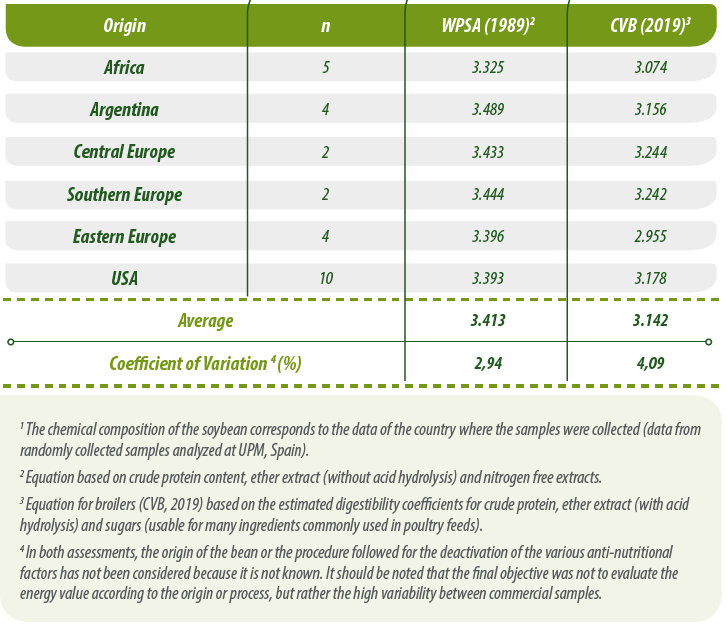

Institutes dedicated to research and information on the chemical composition and nutritional value of raw materials, give values of apparent metabolizable energy corrected in nitrogen (EMAn) for the FFSB in a range between 3,137 and 3,715 kcal / kg (Table 1). The differences between sources of information on the energy value of beans are difficult to explain, but are due, at least partly, to the content and quality of the lipid and protein fraction (Salado et al., 1999; Thakur and Hurburgh, 2007; Serrano et al., 2012) and the sucrose content (Coon et al., 1990; Berrocoso et al., 2014; Ravindran et al., 2014b).