Grain Processing in Cattle Feeding

Adequate nutrition is a crucial factor for the productive performance, health, and well-being of dairy cattle (NRC, 2001). Meeting the nutritional demands of lactating cows is fundamental and simultaneously challenging for dairy herds, especially high-production cows. In this regard, providing highly digestible feed is essential, and for this reason, the use of processed grains is an alternative (FARIA JÚNIOR et al., 2009).

Adequate nutrition is a crucial factor for the productive performance, health, and well-being of dairy cattle (NRC, 2001). Meeting the nutritional demands of lactating cows is fundamental and simultaneously challenging for dairy herds, especially high-production cows. In this regard, providing highly digestible feed is essential, and for this reason, the use of processed grains is an alternative (FARIA JÚNIOR et al., 2009).

Grain processing refers to preparation methods aimed at achieving physical and/or chemical changes in the grain structure, improving digestibility, palatability, and/or inactivating antinutritional factors in feed (FARIA JÚNIOR et al., 2009). Grain processing for feeding dairy cattle aims to increase the availability and utilization of grains in the gastrointestinal tract, improving digestibility (MATHISON, 1996), and can affect the site of digestion (HUNTINGTON, 1997).

During processing, the protein matrix of the endosperm is broken, allowing easy access to starch granules by microbial and/or intestinal enzymes. Moreover, starch gelatinization occurs during processing, making it more available to rumen microorganisms (HALE, 1973). Effects on the digestion site are observed due to processing, with more processed and smaller particle grains tending to show higher ruminal starch digestibility compared to the small intestine (RÉMOND et al., 2004).

Various physical and chemical processing methods can be employed to increase grain digestibility in ruminants. Among the available methods, the main types of processing can be classified into:

- dry processes and

- wet processes, involving high-pressure steam.

Dry methods include grinding and rolling, while wet methods include steam rolling, flaking, and extrusion (MOURÃO et al., 2012).

This work aims to present, characterize, and summarize the main processing methods used in grains for feeding dairy cattle.

Grinding

Grinding involves reducing the size of grain particles through mechanical impact, cutting, or friction (LAGE et al., 2017; MOURÃO et al., 2012). Hammer mills are commonly used for grinding, where the grain is reduced in size through mechanical impact. The particles formed, beyond a certain size, can pass through a sieve, which can vary in calibration, resulting in a fine or coarse appearance depending on desired specifications (SILVA, 2011).

Grinding is the simplest and most cost-effective method of grain processing, and it is also the most widely used. The main factors that can influence the grinding process are:

- sieve size;

- mill capacity and speed;

- type of grain used, and

- grain moisture content (SILVA, 2011).

Effects on Grain

Expected changes in the physical structure and, consequently, the availability of grains results from the grinding process, causing significant changes in starch and protein digestibility (SILVA, 2011).

In addition to reducing particle size, grinding alters the internal structure of grains, eliminating the pericarp and breaking the protein matrix of the endosperm (HALE, 1973).

- The reduction of the physical barrier (endosperm) and the breaking of the endosperm increase the surface area of the grains, facilitating and intensifying the action of ruminal microorganisms and digestive enzymes, enhancing ruminal starch digestibility (FARIA JÚNIOR et al., 2009; LAGE et al., 2017).

Costs

The cost of acquiring a hammer mill is around US$15,000.00, with a production capacity of 15 tons/hour (MFRural; internet).

Dry Rolling

The dry rolling process involves compressing the grain between a series of metal rollers (steel cylinders) that flatten and break the grain into smaller particles.

The particle size generated after the dry rolling process varies depending on the spacing and pressure adjustment between the cylinders. Other factors influencing particle size include the grain flow rate in the equipment and the moisture content of the grain to be rolled (SILVA, 2011).

Effects on Grain

Similar to grinding, the modifications undergone by the grain are only in the physical structure, and more gently.

Dry rolling can increase ruminal digestibility compared to whole grain but has lower ruminal digestibility compared to grinding due to reduced exposure surface to enzymes (HUNTINGTON, 1997).

Additionally, since it does not undergo gelatinization, starch from dry-rolled grains may have lower availability to ruminal microorganisms than in other processing methods (FARIA JÚNIOR et al., 2009). In this sense, the use of dry-rolled grains increases the amount of starch reaching the small intestine compared to grinding.

Costs

The acquisition cost of a dry roller is around US$5,000.00, with a production capacity of 2400 to 3400 kg/hour (MFRural; internet).

Steam Rolling

To carry out the steam rolling process, before grains pass through the roller, a preliminary stage is performed to increase grain moisture to concentrations between 17 and 20%. In a condenser, grains receive steam at 90 – 95°C for 15 to 20 minutes and are then subjected to rolling by a process similar to dry rolling (LAGE et al., 2017). After the rolling process, partially gelatinized grains are dried (MOURÃO et al., 2012).

Effects on Grain

In addition to changes in the physical structure of grains, chemical alterations result from the treatment of grains with steam pressure.

Grains undergo partial gelatinization of starch granules in the steam rolling process.

Gelatinization involves breaking the hydrogen bonds that hold glucose polymers together, allowing water absorption by starch granules, facilitating enzymatic digestion (PLASCENCIA; ZINN, 1996).

Flaking

Flaking presents itself as a modification of the steam rolling process. Similar to steam rolling, before undergoing compression, the grain is subjected to steam application to increase internal moisture.

In the flaking process, the grain is held in a condenser at a temperature of 90 to 105°C for 30 to 60 minutes, raising the moisture to 20 to 24% (FARIA JÚNIOR et al., 2009).

After the condenser, grains undergo compression by rolling cylinders and then pass through a second set of calibrated cylinders with smaller spacing that compress the grain more intensely. Grains after the second set of cylinders have a thickness between 0.9 to 1.1 mm (FARIA JÚNIOR et al., 2009; LAGE et al., 2017).

Effects on Grain

Water vapor increases the temperature of the grains to approximately 100°C, causing hydration and breaking the molecular complex of starch granules, leading to gelatinization (SILVA, 2011).

Due to greater gelatinization and increased availability of starch granules, higher ruminal degradation of grains processed by flaking compared to dry and steam rolling is observed.

Additionally, flaking can provide greater palatability to the grain and consequently increase dry matter intake (PLASCENCIA; ZINN, 1996; SILVA, 2011). The flaking process increases starch digestibility by 10 to 20%, but it causes a decrease in NDF digestibility, possibly associated with increased facilitated starch fermentation (PLASCENCIA; ZINN, 1996).

Cost

The equipment for grain flaking costs an average of US$40,000.00 and can produce 30 tons/hour (Abramilho contact).

Extrusion

Extrusion is a thermomechanical and continuous processing similar to steam rolling but performed with pre-ground grains. The feed is converted into a fluid mass through the combination of moisture, heat, and compression applied to the ground grains in an endless screw (MOURÃO et al., 2012). The mass formed in the process is forced to pass through holes where the feed expands in the direction and is expelled (FARIA JÚNIOR et al., 2009).

Effects on Grain

The expansion undergone by the grains leads to gelatinization, rupture of starch granules, and/or denaturation of protein (LAGE et al., 2017). Furthermore, the extrusion process reduces the specific density of particles (e.g., dry-rolled sorghum: 450-644g/L, wet-rolled: 438-540g/L, and flaked: 360-438g/L), influencing rumen passage rate and consequently digestibility (FARIA JÚNIOR et al., 2009).

Costs

The acquisition cost of an extruder is around US$45,000.00, with a production capacity of 400kg/hour (MFRural; internet).

Effects on Cow Digestive Physiology

Different grain processing methods for cattle feeding aim to promote physical and/or chemical changes in the grain structure that can influence the digestion site (rumen/small intestine) and digestibility, especially starch (MOURÃO et al., 2012).

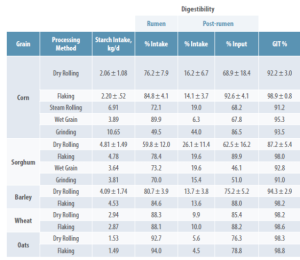

In a systematic review conducted by Huntington (1997), the influence of processing methods on different grains was observed in the percentage of ruminal starch degradation and changes in the starch digestion site in different processes (Table 1).

Table 1. Digestibility Coefficient in the Rumen, Post-rumen, and Total Gastrointestinal Tract (GIT) of Grains subjected to Different Processing Methods.

Adapted from (Huntington, 1997)

The effect of corn processing and particle size on starch digestibility and digestion site was evaluated in two experiments conducted by RÉMOND et al. (2004).

- In the first experiment, using semi-flint corn processed by: a) grinding; b) medium rolling, and c) coarse rolling with particle sizes ranging from 730 to 3668 μm mm. Ruminal starch digestibility was linearly related to particle size, being higher in grinding (59%) and decreasing linearly between processing methods based on particle size up to coarse rolling (36%). Concurrently, small intestine digestibility decreased linearly with particle size increase, and despite higher ileal starch flow, there was no increase in large intestine starch digestion based on particle size.

- In the second study, ground and coarsely rolled dent corn (568 and 3458 μm) were used. Similar to the first study, ruminal starch digestibility was influenced by particle size, being higher for ground corn (70%) and lower for rolled corn (54%). Small intestine starch digestibility was not affected by particle size, but the amount of starch digested in the small intestine tended to be higher for rolled corn than ground corn.

In both studies, small intestine digestibility decreased linearly with ruminal starch escape, associated with digesta transit time.

In addition to increasing ruminal starch digestibility, grain processing can enhance propionic acid production and influence microbial protein synthesis in the rumen, as well as the flow of metabolizable protein to the small intestine (MOURÃO et al., 2012; MARTINS et al., 2019).

To assess the influence of different starch sources and processing forms on productive performance and nitrogen metabolism in lactating cows, (VAZ PIRES et al., 2008) conducted a Latin square study with five cows canulated in the rumen and duodenum. Starch sources used were:

- coarsely ground corn;

- finely ground corn;

- corn flocculated at 310 g/L;

- corn flocculated at 360 g/L, and

- cassava shavings.

Cassava shavings showed higher in vitro hydrolysis rate (p<0.05) than other starch sources tested, and both flocculated corn treatments had higher in vitro starch hydrolysis compared to coarsely ground corn.

In vivo evaluations showed more active ruminal fermentation (indicated by lower rumen ammonia concentration) for flocculated starch sources and cassava shavings. There was no effect of starch sources on nitrogen consumption or the flow of nitrogen fractions to the duodenum, but there was a tendency (p<0.10) for higher microbial nitrogen flow to the duodenum in flocculated corn and finely ground corn diets compared to cassava shavings and coarsely ground corn (Table 2).

The data indicates that increased ruminal starch degradability, provided by grain processing, improved protein metabolism, allowing better synchronization in ruminal fermentation of energy and protein sources. This effect was also observed in plasma urea concentration, which was higher (P<0.05) for cows receiving cassava shavings compared to those receiving flocculated corn.

The relationship between ruminal starch availability and microbial protein synthesis is associated with milk production and composition. Nutritional deficiency can reduce milk stability in the alcohol test (MARTINS et al., 2019).

The relationship between ruminal starch availability and microbial protein synthesis is associated with milk production and composition. Nutritional deficiency can reduce milk stability in the alcohol test (MARTINS et al., 2019).

- Ruminal degradability of starch and protein influences the expression of casein subunits, associated with microbial protein production and the supply of ruminal undegradable protein available for milk synthesis (LI et al., 2014).

- A decrease in the kappa casein percentage is associated with the alcoholic instability of milk, and the degradability of crude protein, along with starch in the rumen, this needs to be adjusted to meet the nitrogen demand for microbial synthesis and the supply of amino acids to the cow.

To evaluate the association between increased starch degradability, N utilization efficiency, and milk composition and stability concerning corn processing, Martins et al. (2019) conducted a balanced Latin square study in five contemporary periods, in a 2×2 factorial arrangement with 20 dairy cows.

The first factor considered was corn processing, with treatments: a) ground corn (average of 952 ± 1.86 μm particle size), or b) flocculated corn (density of 280 g/L).

The second factor considered was crude protein degradability: a) high: 107 g rumen-degradable protein/kg dry matter and 51 g rumen-undegradable protein/kg dry matter, or b) low: 95 g rumen-degradable protein/kg DM and 63 g rumen-undegradable protein/kg DM.

There was an interaction effect between corn processing and crude protein degradability on dry matter intake, with cows fed ground corn and low degradability protein showing increased dry matter intake (1.73 kg/d), increased milk production by 2.3 kg/d, and increased heat coagulation time (a measure of milk stability) by 4.8 min compared to cows fed ground corn and high degradability protein.

Cows fed flocculated corn had higher digestibility of dry matter, starch, crude protein, and ether extract, and the diet with ground corn and low crude protein digestibility had lower apparent NDF digestibility than the others (p = 0.041).

There was no interaction between corn processing, protein degradability, and casein subunit expression, nor milk protein content.

- However, cows fed low degradability crude protein diets had higher kappa casein content, as well as milk protein content, and nitrogen use efficiency for milk production than cows fed high degradability crude protein diets.

Although flocculated corn reduced dry matter intake (which may be related to increased hepatic oxidation of propionic acid, facilitated by increased ruminal starch digestibility; MARTINS et al., 2019), no effect was observed on milk production compared to groups fed ground corn, indicating higher productivity in cows fed flocculated corn. The results suggest that recommendations for crude protein degradability in lactating cow diets should correlate with the source and ruminal starch availability, associated with grain processing. Overall, in response to the flow and availability of amino acids for milk protein synthesis, crude protein degradability is correlated with milk stability.

CONCLUSIONS

Grain processing techniques can increase the digestibility of feed, influencing the starch digestion site, favoring ruminal degradability, and influencing ruminal microbial protein synthesis.

Physical changes associated with breaking the grain pericarp protein matrix and decreasing particle size are associated with increased ruminal degradability and total digestibility of grains.

Additionally, gelatinization promoted by wet processing involving steam, temperature, and pressure facilitates enzymatic action on starch granules. In this sense, the use of processed grains constitutes an alternative to meet the nutritional demands of ruminants and increase the digestibility of feeds used in cattle nutrition.

References upon request.