Cereal milling has great impact in pig health and production costs. Pig feed costs account for 65-80% of total production costs (Jensen, 1976). This has led producers to take advantage of feed manufacturing practices to maximise the use of raw materials.

Properly managed, the increase in the cost associated with the manufacture of feed translates into an improvement in the performance of pigs.

Good manufacturing practices are essential to ensure a low cost-benefit ratio.

Not only is it important to fully understand each processing method and its effects, but you also need to understand how processing influences:

- feed handling characteristics

- production costs

- the digestibility of nutrients and energy

- and pig yield

Grains are the main ingredient in pig feed susceptible to grinding. Other ingredients are pre-processed and arrive at the feed mill under acceptable conditions.

There are two types of mills commonly used to reduce the particle size of ingredients, roller mills and hammer mills.

Roller mills

Roller mills reduce particle size by crushing or grinding, thanks to the application of a compressive force on the ingredient.

This process produces a small amount of fine material resulting in a relatively uniform particle size of the grain.

Hammer mills

Hammer mills reduce the particle size of ingredients by impact grinding (Pfost, 1976), resulting in particles with a more spherical shape and increasing the amount of fine, pulverized particles, resulting in a less uniform particle size (Koch, 2002).

Previous studies have shown that the increase in the amount of non-uniform particles generated by the use of hammer mills results in a greater angle of fall, which translates into a worse fluidity (Groesbeck et al., 2006).

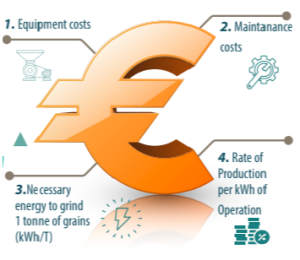

Costs asocciated with milling

On the other hand, in addition to reducing handling characteristics, grinding grains increases the costs associated with milling. These costs include:

The initial cost of equipment may seem expensive, but depending on the mill, energy costs for a year may exceed the costs of a new piece of grinding equipment. Understanding the variety of factors that influence the efficiency and production rate of milling can be very beneficial for feed manufacturers.

![]() The energy required for the operation of a roller mill or hammer mill over its entire service life will be 10-20 times greater than the cost of the machine alone (Heimann, 2014).

The energy required for the operation of a roller mill or hammer mill over its entire service life will be 10-20 times greater than the cost of the machine alone (Heimann, 2014).

Some data shows that reducing the particle size of cereal grains leads to increased energy requirements and a reduction in the production rate (Gebhardt et al. 2018).

The rate at which these factors change can be altered by:

- the grain

- the type of mill

- grinding parameters

- and the maintenance of the mills

Roller mills and hammer mills have different operating costs and require different levels of investment

Considering the negative effects of particle size reduction on milling efficiency, it is important to further investigate whether these losses are justified by improvements in animal performance.

The idea of reducing the particle size of grains before feeding pigs with them came about in the early 30s.

- Grains have a protective outer layer that makes it difficult for digestive enzymes to access all of its nutrients.

- Reducing the particle size of grains through milling exposes protected areas to the action of digestive enzymes, allowing the pig to digest a greater portion of nutrients.

- Fraps (1932) used ground sorghum to show that reducing particle size improved the digestibility of nutrients.

- Aubel (1945, 1955) continued to work on this idea, demonstrating improvements in feed efficiency when pigs were fed ground corn and sorghum grains.

[register]

These experiments laid the groundwork for many zootechnicians to determine the optimal way to apply this processing method in pig production.

- Owlsey et al. (1981) observed an improvement in apparent ileal digestibility (AID) and apparent total tract digestibility (ATTD) of dry matter (DM), nitrogen (N) and crude energy of sorghum in fattening pigs by reducing particle size from 1.262μm to 471μm.

Previous studies have also demonstrated improvements in nutrient digestibility thanks to reduced particle size in corn (Lawrence, 1967; Giesemann et al., 1990).

However, recent studies revealed differences in the digestibility of particles of different sizes depending on the type of mill used to grind corn.

* When employing a hammer mill to grind corn, authors observed no improvements in energy and nutrient digestibility when the particle size was reduced from 700μm to 300μm. However, when corn was ground with a roller mill, improvements in energy and nutrient digestibility were observed (Patience, 2015).

- In contrast, Rojas and Stein (2015) described a linear decrease in the concentration of metabolizable energy (ME) in corn as the size was reduced from 865μm to 339 μm by a hammer mill.

- However, Bertol et al. (2017) developed a model that established that from a size of 523-524μm the value of the apparent metabolizable energy corrected for nitrogen (AMEn), for corn was not improved.

- Based on several studies conducted before 2012, it was concluded that there was a 1.0-1.3% improvement in the efficiency of fattening pigs per 100μm reduction in corn or sorghum particle size when these were reduced from 1,000μm to 400μm (Cabrera, 1995; Wondra, 1995a; Paulk, 2011; De Jong 2012).

- Bertol et al. (2017) observed a 6% improvement in feed efficiency when nulliparous sows received diets with ground corn to go from a size of 904μm to 483μm. However, the reduction in size did not influence the feeding efficiency of the neutered males.

- In contrast to a previous study, Gebhardt et al. (2018) observed no improvements in the feed efficiency of fattening pigs when offering them ground corn with small particles (from 581μm to 285μm) obtained by using a roller mill.

- As mentioned, Bertol et al. (2017) and Rojas et al. (2015) recorded an increase in ME in corn when particle size was reduced. When formulating balanced diets based on this increase in ME, there were no differences in the feed efficiency of fattening pigs.

It is well documented that reducing the particle size of grains improves feed efficiency of pigs. However, previous studies reveal greater variability as to what can be considered the optimal particle size.

The rate of growth in response to the reduction in particle size is more variable in piglets at weaning. It was observed that the weight gain is lower when the corn fraction is ground with fine particles (approximately 325μm).

- This phenomenon is associated with a reduction in food intake, without influencing food efficiency. (De Jong et al., 2013a; De Jong et al., 2013b).

- However, Bokelman et al. (2014) did not observe a significant impact of particle size on weight gain or intake. They instead observed an improvement in feed efficiency by reducing particle size from 700μm to 4000μm when the diet was supplied in flour form.

- The texture and palatability of the corn fraction in finely ground diets reduces the intake in weaned piglets (Sola-Oriol et al., 2009).

- It has been shown that when given the choice, pigs consume 67% or 8% of the average daily intake if given a diet with a fraction of corn ground to 525μm or 700μm, and 33% or 20% in the case of corn ground to 267μm or 400μm, respectively (Bokelman et al., 2014; Gebhardt et al. 2018).

![]()

Weaned piglets are sensitive to diet palatability and a predictable intake reduction is frequently observed when the particle size is less than 500μm.

![]()

While reducing the particle size of grains can improve pig performance, it can have negative effects on gastric morphology.

Certain situations can lead to increased ulceration of the esophageal region of the pig’s stomach.

- Common feed manufacturing practices, such as fine milling, have been shown to increase the incidence of ulceration of the esophageal region of the stomach in fattening pigs (Mahan et al., 1966; Maxwell et al., 1970; Cabrera et al., 1995; Wondra et al., 1995a; and Ayles et al., 1996) and in lactating sows (Wondra et al., 1995b). It has been hypothesized that this is due to an increase in the fluidity of the gastric contents, which ruslts in a greater mixture of them.

- The mixture of this fluid content allows a continuous exposure of the unprotected mucosa of the esophageal region to pepsin and gastric acids (Reimann et al., 1968; Maxwell et al., 1970).

- The relationship between the severity of ulcers and their influence on growth rate is till not well established. Nontheless Hedde et al. (1985) and Ayles et al. (1996) established that increased ulcer severity was associated with decreased weight gain.

- However, other studies indicate that gastric ulcers do not affect growth rate (Backstrom et al., 1988; Guise et al., 1997; Dirkzwager et al., 1998).

- In addition to the effects on performance, severe gastric ulcers can result in sudden death of pigs.

[/register]