Nutritional formulas are a critical part of profitable pig production. It is generally accepted that feed represents between 60-70% of production costs and affects many aspects of the business, including:

| Ingredient procurement Quality control Feed mill processes

|

Feed is the most important input for the production system and is the key driver of pig performance.

This underscores the importance of accurately defining nutrient specifications for each production phase to attain animal performance objectives, a critical process accomplished through diet formulation.

After determining nutritional requirements and formulating diets, the temptation to think, “they’re completed, and we can forget about them,” may arise.

![]() However, it is crucial to understand that nutrient content and ingredient prices are dynamic and continuously fluctuating.

However, it is crucial to understand that nutrient content and ingredient prices are dynamic and continuously fluctuating.

| Taking this into consideration, the following question arises: Is it necessary to revise my dietary formulations? |

There are many reasons to consider reformulating or updating diets. Some of these include:

|

|

|

Moreover, variations in pork prices impact profitability, necessitating the reformulation of diets to adapt to production cost changes and uphold profit margins. Illustratively, in instances of reduced carcass selling prices, the diminished profit margin may influence the incorporation of substitute ingredients like soybean oil, white grease, and additives aimed at enhancing weight gain and feed conversion. |

Furthermore, there is another important question we must ask ourselves:

The process of changing diets is time-consuming and impacts ingredient procurement requirements. Hence, it is crucial to set a minimum threshold for reducing diet costs to prevent frequent changes.

Some systems update ingredient prices and raw material quality information, i.e., nutrient content, weekly, while others prefer to do it monthly.

On the flip side, some prefer an opportunistic approach, making changes as necessary or in response to notable shifts in prices or ingredient quality. However, this approach lacks technical accuracy; a more systematic method, following a regular schedule, would probably result in greater savings.

Below are two examples provided to demonstrate potential cost savings achievable when the price of an ingredient or the nutrient content of a crucial ingredient undergoes a change. In both instances, the following base prices for ingredients were utilized (in USD/ton):

![]() Corn: $230

Corn: $230

![]() Soybean meal: $493

Soybean meal: $493

![]() DDGS (Dry Distillers Grains with Solubles): $254

DDGS (Dry Distillers Grains with Solubles): $254

![]() Wheat middlings: $249

Wheat middlings: $249

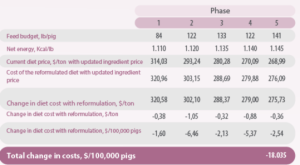

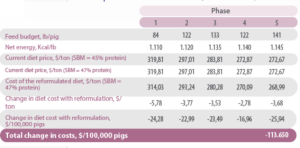

| Table 1 shows a cost comparison of the diet when the price of DDGS increased from $254/ton to $325/ton. The current diet cost significantly increases (around $6-8/ton) as the price of DDGS rises. . |

Table 1 -Reference values for diet quality for pigs and humans

Table 2 shows what can happen if the nutrient level of a key ingredient changes significantly.

Table 2 – Effect of change in soybean meal protein content with/without diet reformulation

![]()

In this example, the current diet costs were based on a soybean meal protein value of 45%.

|

If the protein content in soybean meal undergoes a change, but we fail to measure it, the diets will remain unaltered. Yet, with even a basic quality control program in place to consistently measure nutrient levels in essential ingredients, there is an opportunity to realize savings in the nutrient content of soybean meal. This allows for the reformulation of diets, resulting in savings of several dollars per ton. |

The cumulative savings per pig exceed $1.13, totaling over $113,000 for 100,000 pigs. If this nutrient shift were to happen in reverse (e.g., 47% soybean meal protein decreasing to 45%) without detection, the diets would no longer align with the originally formulated target nutrient levels.

Consequently, this would lead to diminished pig performance, an extended period to attain market weight, and increased feed usage due to inferior feed conversion.

Consequently, this would lead to diminished pig performance, an extended period to attain market weight, and increased feed usage due to inferior feed conversion.

This, in turn, would result in lost revenue owing to reduced daily gain and final weight.

CONCLUSIONS

|

Implementing a robust quality control program that routinely measures nutrient levels in key ingredients (especially those frequently included in diets like corn, soybean, wheat, DDGS), coupled with periodic price updates, is a crucial initial step in identifying opportunities for cost savings. This information can then be utilized to revise feed formulations at least once a month, to achieve cost savings. |

You may also like to read: “Soybean Origin Segregation in Poultry Feed: A Precision Nutrition Approach”

These instances underscore the importance of regularly monitoring nutrient levels in ingredients and adjusting diet formulations to achieve savings or meet nutrient requirements in an effective and cost-efficient manner.

These instances underscore the importance of regularly monitoring nutrient levels in ingredients and adjusting diet formulations to achieve savings or meet nutrient requirements in an effective and cost-efficient manner.