Beer bagasse is highly appreciated in animal feed

Definition and classification

21 Nov 2022

21 Nov 2022

Beer bagasse is highly appreciated in animal feed

Definition and classification

Brewer’s spent grains is a by-product of beer production.

In its natural form it is a wet paste that results from the process of malting, maceration and filtering of the wort obtained after the saccharification of cereal grains (barley, corn, rice, sorghum,…), used for the manufacture of beer.

→ Beer bagasse is highly appreciated in animal feed for its high protein and fiber content.

→In addition, its high proportion of phenolic acids with antioxidant properties, such as ferulic acid, and arabinoxylans with prebiotic, antioxidant and immune activity, increase its interest not only at the nutritional level but also as an ingredient with potential to improve the health of animals.[ registered]

The “Catalogue of raw materials” (Regulation (EU) No 68/2013) defines several specific by-products related to the manufacture of beer for animal feed, as well as the mandatory declarations for these products (Table 1).

Table 1. Products from the Catalogue of Raw Materials (Regulation (EU) No. 68/2013) related to the manufacture of beer.

Beer bagasse is the majority by-product, accounting for 85% of the waste produced in the brewing process.

→ This includes the grain shell, pericarp and endosperm fragments→ It is not a seasonal by-product, although its production is generally higher in summer (due to the greater demand for beer).

To improve its conservation, its reuse involves a previous pressing process, which reduces its humidity from 80% to 60%, approximately.

In the case of beer bagasse, as for most distillery products, the nutrients to be declared are moisture and protein.

| Its revaluation in animal feed contributes to the implementation of a circular economy in brewing. |

Procurement process

Figure 1 shows a general scheme of the main stages in brewing.

↣ Bagasse is the by-product obtained after filtration of brewing wort, obtained after malting (or germination) of cereal grains and subsequent drying, grinding and maceration of malts.

↣ During the maceration process, the enzymes produced in malting transform starch into fermentable sugars and proteins into peptides and amino acids, which constitute nitrogenous sources for subsequent fermentation (Martínez-Muñoz, 2015).

Figure 1. General brewing process

Chemical composition and nutritional value

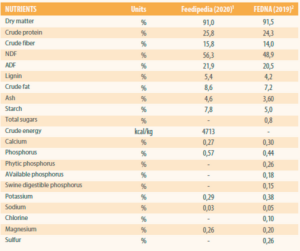

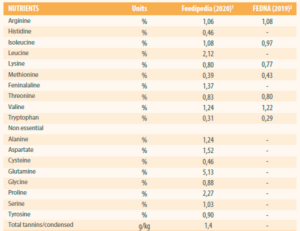

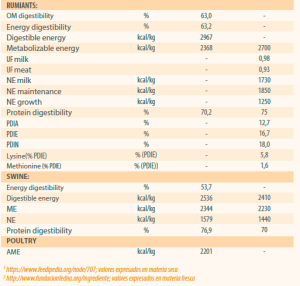

Table 2 shows the composition of beer bagasse according to different sources.

>In fresh, it contains a low content of dry matter, between 20-25%.

> Dry, it is an ingredient rich in fiber and protein..

Finally, its fat content is variable, and depends on the type of cereal of origin and its metabolizable energy content is moderate in all species (2200-2700 kcal / kg).

Table 2.Chemical composition of dehydrated beer bagasse (dry matter)

Use in animal feed

Beer bagasse in wet form is mainly intended for dairy cattle feed (fresh or silaged) as it is an excellent source of non-degradable protein (by-pass), capable of satisfying much of the protein and amino acid needs of these animals (Negash, 2021).

In addition, they are an excellent source of fiber potentially usable by these animals.

The inclusion of between 20-30% in dairy cattle rations is possible without modifying yields and in vitro digestibility (Murugan et al., 2014; Wang et al., 2020).

Currently, it is possible to dehydrate it to be used in feeding other species such as pigs or birds, although its nutritional value in these species is still little known.

In monogastrics , the digestibility of their protein and energy is generally expected to be lower (Sol et al., 2016).

However, both the type of fiber it contains and its content in ferulic acid, one of the phenolic acids with the highest presence in bagasse, can exert positive effects on the intestinal health of animals due to its prebiotic, antioxidant, antimicrobial and anti-inflammatory effect (McCarthy et al. , 2013).

In addition, its arabinoxylan content can also exert positive effects on immune function and on lipid metabolism and glucose, triglyceride and cholesterol metabolism (Steiner et al., 2015).

Conclusions

The efficient use of by-products generated in the brewing process has a direct impact on the economy and environmental pollution and contributes to sustainable beer production. Currently, the main destination of these by-products is animal feed.

It contains an interesting level of protein and fiber ideal for ruminants and with the possibility of being used in pigs and poultry, although in smaller proportions.

Its high content of biocompounds (phenolic acids and arabinoxylans) gives it antioxidant and prebiotic capacity.

[/register]

Subscribe now to the technical magazine of animal nutrition

AUTHORS

Nutritional Interventions to Improve Fertility in Male Broiler Breeders

Edgar Oviedo

The Use of Organic Acids in Poultry: A Natural Path to Health and Productivity

M. Naeem

Synergistic Benefits of Prebiotics and Probiotics in Poultry, Swine, and Cattle

Gustavo Adolfo Quintana-Ospina

Hybrid Rye Potential in Laying Hen Feed Rations

Gwendolyn Jones

A day in the life of phosphorus in pigs: Part I

Rafael Duran Giménez-Rico

Use of enzymes in diets for ruminants

Braulio de la Calle Campos

Minerals and Hoof Health in the Pregnant Sow

Juan Gabriel Espino

Impact of Oxidized Fats on Swine Reproduction and Offspring

Maria Alejandra Perez Alvarado