07 Sep 2022

07 Sep 2022

Cereal grain processing aims to increase their nutritional value, making them more usable for pigs and poultry. Which in turn results in a reduction of feed volumes.

Processing methods can be separated into two large groups: “cold” and “heat”.

Cereals respond differently to processing conditions. Therefore, each cereal has special recommendations regarding the processing technique that best suits them.

Importance of processing

Cereal processing represents a significant tool for piglet diets. Piglets unlike newborn chicks do not possess the ability to properly digest starch. Weaned piglets between 21 and 28 days of age have a comparatively immature digestive system and their pancreatic α-amylase levels are deficient. The development of their full digestive capacity is reached at approximately 10 weeks of age.

Digestive problems in pigs are common during weaning, with one of the main causes being the incapacity to digest starch properly. Considering that cereals make up the biggest part of pig diets and that piglets lack high enzymatic activity, it is natural for these types of problems to occur.

[register]

Starch structure

Starch is the main component of cereals. It usually represents between 60 and 70% of their total weight.

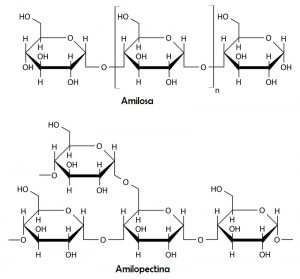

Starch is made up of two main polymers, amylose and amylopectin. Both are formed by chains of glucose molecules, which are linked by α1-4 bonds in the case of amylose; and by α1-4 and α1-6, in the case of amylopectin, which has ramifications (Figure 1). A greater presence of amylopectin in relation to amylose, will increase starch’s digestibility. This is due to the fact that the presence of branched chains facilitates enzymatic attack.

Figure 1

Modification of starch structure through processing

Starch granules are insoluble in cold water. When heated in presence of water, starch granules begin to absorb water, swelling and finally breaking. At this point, such transformation becomes irreversible. This process is known as “gelatinization” and occurs within a temperature range of 60 to 70ºc in cereals. This is a gradual process that continues as the temperature increases and ends when amylose chains are highly hydrated forming a paste. When cereals are subjected to dry heat, gelatinization occurs at a higher temperature, o approximately 100 ºc.

The purpose behind this process is to improve starch digestibility and thus be able to obtain more energy from cereals. However, excess heating can result in reduced nutrient availability. In addition to damaging starch, the digestibility of proteins and amino acids can also be negatively affected.

Milling

Grinding aims to reduce grains’ particle size in order to increase the action surface for digestive enzymes. As it does not use heat, this process does not modify structure and therefore the digestibility of starch does not change significantly.

Unlike poultry, pig diets must always contain ground grains, since they practically do not chew their feed when ingesting it. Therefore whole grain diets are less palatable and yields are worse. However, the degree of grinding should not be so high as to generate dust formation problems. If particle sizes are too thin this can generate ulcers in pigs’ stomachs. Birds on the other hand, are able to use whole grains thanks to the grinding action of the gizzard.

Popping

Popping is a method where dry heat is applied at high temperatures. The grain’s internal water is transformed into steam and this makes it swell.

Extrusion

Extrusion requires prior conditioning of the cereals, where steam is applied. Cereals are subjected to high pressure and temperature (between 130 to 160 °c) and then pressed against a matrix. They then exit through the matrix’s holes.

Micronization

Micronization is a processing system that includes the application of heat through the use of microwaves after getting the grains to 18% humidity. It consists of a short cooking process at high temperatures. Cereals, oilseeds, beans and legumes heat up quickly. Cereal grains for example reach a surface temperature of 100ºC in 45 seconds. Drying is unnecessary for this process which saves energy. It also improves palatability, by converting starches into sugars, improving its flavor when compared to other processes.

Conclusions

[/register]

Subscribe now to the technical magazine of animal nutrition

AUTHORS

Nutritional Interventions to Improve Fertility in Male Broiler Breeders

Edgar Oviedo

The Use of Organic Acids in Poultry: A Natural Path to Health and Productivity

M. Naeem

Synergistic Benefits of Prebiotics and Probiotics in Poultry, Swine, and Cattle

Gustavo Adolfo Quintana-Ospina

Hybrid Rye Potential in Laying Hen Feed Rations

Gwendolyn Jones

A day in the life of phosphorus in pigs: Part I

Rafael Duran Giménez-Rico

Use of enzymes in diets for ruminants

Braulio de la Calle Campos

Minerals and Hoof Health in the Pregnant Sow

Juan Gabriel Espino

Impact of Oxidized Fats on Swine Reproduction and Offspring

Maria Alejandra Perez Alvarado