21 Jul 2024

21 Jul 2024

IMPORTANCE OF AFLATOXIN CONTROL IN ANIMAL FEED

Globally, from 60% to 80% of crops are contaminated by mycotoxins, with more than 20% exceeding the legal food safety requirements in the European Union (EU) (FAO 2004).

Corn is the main affected cereal,followed by wheat, with a growing presence of aflatoxins, fumonisins, and deoxynivalenol (DON) (Smith et al. 2016).

Mycotoxins in feed can cause acute or chronic effects on various organs, with a higher risk of chronic intoxication and liver damage.

![]() The determining parameters of damage include the duration of exposure,

The determining parameters of damage include the duration of exposure,

species, age, health and nutritional status of the animals, and the concentration of mycotoxins present (Richard 2007).

DESCRIPTION OF AFLATOXINS

![]() Aflatoxins are toxic compounds produced by certain fungi of the Aspergillus genus, mainly Aspergillus flavus and Aspergillus parasiticus.

Aflatoxins are toxic compounds produced by certain fungi of the Aspergillus genus, mainly Aspergillus flavus and Aspergillus parasiticus.

These fungi can contaminate grains during cultivation, harvest, storage, and feed processing, especially in conditions of high humidity and temperature.

These fungi can contaminate grains during cultivation, harvest, storage, and feed processing, especially in conditions of high humidity and temperature.

Aflatoxins are common in animal production, and their presence can significantly worsen productive indices, causing growth retardation, increased mortality, reproductive problems, and weakened immune systems (CAST 2003).

Aflatoxins are classified into several types, the most important being aflatoxins B1, B2, G1, and G2. The B and G types are the most dangerous due to their carcinogenic potential, mainly affecting the liver but also causing damage to the lungs, colon, and kidneys (IARC 2012).

Aflatoxin B1 is the most prevalent and toxic, strongly implicated in the development of liver cancer. The first case of aflatoxicosis (aflatoxin intoxication) was reported in the 1960s in turkeys in the United Kingdom.

To prevent the proliferation of aflatoxins, it is crucial to maintain feed moisture below 10-12% and relative humidity below 70% (Bryden 2012).

To prevent the proliferation of aflatoxins, it is crucial to maintain feed moisture below 10-12% and relative humidity below 70% (Bryden 2012).

TOXICITY AND MECHANISM OF ACTION

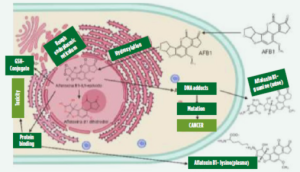

The toxicity of aflatoxins lies in their ability to be transformed into reactive epoxides in the liver, which can bind to DNA and other macromolecules, inhibiting protein and RNA synthesis.

et al. 2004). |

Note. Mechanism of action of AFB1, development of conjugates and adducts.

Adapted from Barragán Quishpe. Importance of aflatoxin detection in nuts, in food safety.

2020.

Acute intoxication is characterized by symptoms such as jaundice, liver failure, and in severe cases, death.

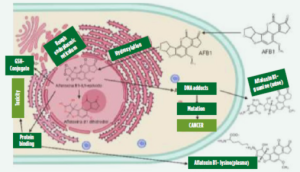

![]() In its chronic form, there is a decrease in feed intake and growth, liver damage, reproductive problems, and digestive disorders (Llewellyn et al. 1992).

In its chronic form, there is a decrease in feed intake and growth, liver damage, reproductive problems, and digestive disorders (Llewellyn et al. 1992).

Birds, pigs, rabbits, and ruminants are the species most sensitive to aflatoxicosis (Rawal et al. 2010).

Hepatic vacuolization. Yellowish coloration and hepatic hemorrhages.

QUANTIFICATION

Diagnosing aflatoxin contamination is based on the quantification of mycotoxins in food, stomach contents, tissues, milk, blood, and urine (Shephard 2009).

Diagnosing aflatoxin contamination is based on the quantification of mycotoxins in food, stomach contents, tissues, milk, blood, and urine (Shephard 2009).

Representative sampling is essential for accurate results. The most common detection methods include ELISA for rapid detection and high performance liquid chromatography (HPLC) and gas chromatography (GC) for precise confirmation and quantification (Shephard 2008).

Accurate quantification of aflatoxins is crucial to determining the most suitable and effective detoxification methods.

Aflatoxin levels can vary significantly between different feed batches, making thorough and representative sampling necessary for an accurate risk assessment.

DETOXIFICATION METHODS

Controlling and eliminating aflatoxins in feed is crucial due to their high toxicity and ability to negatively affect animal and human health.

Various detoxification methods can be applied to reduce or eliminate aflatoxins in food, classified into physical, chemical, and biological methods.

Physical Methods

1| Thermal Treatment: Applying heat can reduce

aflatoxin concentration in food. However, this method is not always completely effective, as aflatoxins are relatively heat-stable and may require very high temperatures to achieve significant reduction, potentially negatively affecting the nutritional quality of

food.

2| Cleaning and Separation: Mechanical cleaning and separation of contaminated grains can reduce aflatoxin load. Methods like density classification, screening, and color separation are used to remove grain parts with the highest toxin concentrations.

3| Radiation: Ultraviolet (UV) light or gamma radiation has been studied as a method to break down aflatoxins. Although effective, its large-scale implementation is limited by costs and necessary infrastructure.

Chemical methods

1| Use of Adsorbents: Adsorbents are materials that can bind to aflatoxins and prevent their absorption in the digestive tract. Common adsorbents include clays (like bentonite), activated charcoal, and yeast cell walls. These materials are added to animal feed and act by trapping aflatoxins during digestion, reducing their bioavailability (Galvano et al. 2001).

2| Treatment with Chemical Agents: Using chemicals like ammonia, hydrogen peroxide, and organic acids can break down aflatoxins into less toxic compounds. Ammonization, for example, is widely used to treat corn and other grains and has proven effective in reducing aflatoxins.

3| Antioxidant Additives: Adding antioxidants to feed can help prevent aflatoxin formation. Natural antioxidants like vitamins E and C and phenolic compounds have shown promising effects in reducing aflatoxin synthesis by fungi.

Biological Methods

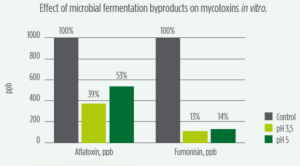

1| Biotransformation: Biotransformation involves using microorganisms or enzymes to degrade aflatoxins into less toxic compounds. Various studies have identified bacteria, yeasts, and fungi capable of breaking down aflatoxins. For example, certain strains of Lactobacillus and Bacillus have shown the ability to degrade aflatoxin B1 (Dohnal et al. 2014).

2| Fermentation: Fermentation can reduce aflatoxin concentration in food. During fermentation, microorganisms produce enzymes that can degrade aflatoxins. This method is used in the production of fermented foods like cheese and yogurt.

3| Use of Plant Extracts: Some plant extracts contain bioactive compounds that can inactivate aflatoxins or inhibit the growth of aflatoxin-producing fungi. For example, extracts from plants like neem, garlic, and turmeric have shown antifungal effects and can be used as feed additives to reduce aflatoxin contamination.

Combined methods

Combining different detoxification methods can result in greater efficacy in reducing aflatoxins. For example, using adsorbents along with thermal or chemical treatments can provide a double barrier against aflatoxins.

Additionally, integrating biological and chemical methods can offer a more comprehensive and sustainable solution for aflatoxin control.

Conclusions

|

Visit liptosa.com

Subscribe now to the technical magazine of animal nutrition

AUTHORS

Nutritional Interventions to Improve Fertility in Male Broiler Breeders

Edgar Oviedo

The Use of Organic Acids in Poultry: A Natural Path to Health and Productivity

M. Naeem

Synergistic Benefits of Prebiotics and Probiotics in Poultry, Swine, and Cattle

Gustavo Adolfo Quintana-Ospina

Hybrid Rye Potential in Laying Hen Feed Rations

Gwendolyn Jones

A day in the life of phosphorus in pigs: Part I

Rafael Duran Giménez-Rico

Use of enzymes in diets for ruminants

Braulio de la Calle Campos

Minerals and Hoof Health in the Pregnant Sow

Juan Gabriel Espino

Impact of Oxidized Fats on Swine Reproduction and Offspring

Maria Alejandra Perez Alvarado