21 Dec 2023

21 Dec 2023

Influence of the Compost Barn System on the Nutrition, Production, and Quality of Milk

All confinement systems for dairy cattle aim to improve comfort for the animals, allowing them to express their natural behavior while maintaining hygiene and health, and generally enhancing the living conditions of lactating animals and the financial situation of the producer. Among the confinement systems employed in dairy farming, the Compost Barn (CB) has stood out.

All confinement systems for dairy cattle aim to improve comfort for the animals, allowing them to express their natural behavior while maintaining hygiene and health, and generally enhancing the living conditions of lactating animals and the financial situation of the producer. Among the confinement systems employed in dairy farming, the Compost Barn (CB) has stood out.

The installation of the CB is a relatively new system worldwide, becoming increasingly popular in South American countries, especially in Brazil, Argentina, Uruguay, and Paraguay. This system has been successfully constructed and operated for some time in Israel and the United States. Some of the current scientific findings on this type of animal husbandry system come from the U.S., especially from the states of Minnesota and Kentucky.

![]()

It is a confinement model in which animals roam freely in a large area covered with organic bedding, allowing them to move and express their behavior more naturally.

Usually, the Compost Barn (CB) system comprises two primary areas:

![]() Resting area with bedding.

Resting area with bedding.

![]() Feeding alley with grooved concrete floor.

Feeding alley with grooved concrete floor.

In certain setups, there might be an additional service corridor designed to assist in directing animals to the milking parlor. Various organic materials have been utilized as carbon sources in the bedding area, including:

![]() Wood shavings and sawdust

Wood shavings and sawdust

![]() Peanut husk

Peanut husk

![]() Coffee husk

Coffee husk

![]() Wheat straw

Wheat straw

![]() Soybean straw

Soybean straw

![]() Rice straw

Rice straw

Nevertheless, in areas where the supply is restricted or during material shortages, alternative organic materials have been effectively employed. Occasionally, a mixture of sawdust with soil has been noted, though its efficacy in this context lacks proven evidence. In this system, both feces and urine are deposited and integrated into the organic material within the bedding area.

![]()

The integration of animal waste takes place while turning the bedding material, utilizing an implement (such as a subsoiler, rotary hoe, etc.) attached to the tractor.

![]() The turning of the bedding material should occur at least twice a day when cows are being milked.

The turning of the bedding material should occur at least twice a day when cows are being milked.

However, under certain circumstances where labor is scarce, producers may opt to confine the cows in the feeding alley before the bedding turning process. This procedure seeks to loosen the surface material, encourage the blending of bedding and waste, enhance porosity (void space), and elevate oxygen concentrations within the bedding material.

Failure to conduct regular and proper turning can result in bedding compaction, diminishing oxygen availability for decomposing microorganisms and impeding material degradation.

![]() Oxygen supply is essential for the satisfactory aerobic decomposition of bedding material, and its demand increases with the degradation speed.

Oxygen supply is essential for the satisfactory aerobic decomposition of bedding material, and its demand increases with the degradation speed.

Dietary Requirements of Dairy Cows in the Compost Barn System

![]()

The housing system for dairy cows should offer improved thermal comfort and increased flexibility for producers dealing with groups of animals in the same physiological stage. Among various confinement systems, the Compost Barn (CB) has demonstrated superior welfare conditions and enhanced flexibility when managing groups of animals at similar physiological stages.

European dairy breeds specialized for high milk production are particularly susceptible to heat stress, a prevalent condition in Brazil given its tropical climate. Dairy cows with elevated milk production require conditions that allow them to fully express their genetic potential, including:

![]() An environment with adequate comfort

An environment with adequate comfort

![]() Access to water and feed intake

Access to water and feed intake

![]() Comfortable beds that increase resting time

Comfortable beds that increase resting time

![]() Facilities that provide good thermal comfort conditions

Facilities that provide good thermal comfort conditions

| Furthermore, nutritional strategies need to be carefully coordinated to prevent metabolic disorders, particularly during the transition period, as these can significantly affect the entire lactation of the animal. |

Heat stress initiates metabolic and behavioral changes in the herd. In practice, it has been observed that in conditions of thermal discomfort, cows reduce dry matter intake and spend more time standing, increasing their respiratory rate in an attempt to dissipate body heat to the environment.

![]() All these conditions result in higher energy expenditure during this interval of reduced dry matter intake, leading to lower milk production, directly affecting animal health. Another behavioral factor that increases during heat stress is feed selection at the trough, which can be a risk factor for acidosis in animals and a decrease in milk solids content.

All these conditions result in higher energy expenditure during this interval of reduced dry matter intake, leading to lower milk production, directly affecting animal health. Another behavioral factor that increases during heat stress is feed selection at the trough, which can be a risk factor for acidosis in animals and a decrease in milk solids content.

Additionally, if lactating cows do not lie down for at least 12 hours a day, it will also lead to reduced production. In other words, for each additional hour of rest, cows will produce 1.6 liters more milk per day.

Dairy cows possess nutritional requirements for both maintenance and production, with these requirements varying according to their physiological condition. Throughout the transition period, which spans 21 days before calving and 21 days post-calving, the primary focus of nutrient demand is on:

![]() Fetal growth

Fetal growth

![]() Mammary gland preparation in the last days of gestation

Mammary gland preparation in the last days of gestation

![]() Colostrum production, and

Colostrum production, and

![]() After calving, milk synthesis

After calving, milk synthesis

A vital aspect during the transition period is the eating behavior of cows, as physical, behavioral, environmental, physiological, and metabolic changes in the animal significantly impact performance. Each additional liter of milk achieved during the lactation peak contributes to an extra 200 liters of milk throughout lactation. It’s crucial to emphasize that the maximum feed intake by animals occurs only when cows have adequate time for their meals.

Production of Dairy Cows in the Compost Barn System

[register]

![]() One significant hurdle in dairy farming, leading to a rise in mastitis cases within the herd, is the intensification of cow production. Nevertheless, akin to any production chain, dairy producers encounter daily challenges in sustaining herd productivity.

One significant hurdle in dairy farming, leading to a rise in mastitis cases within the herd, is the intensification of cow production. Nevertheless, akin to any production chain, dairy producers encounter daily challenges in sustaining herd productivity.

In the pursuit of greater productivity and efficiency in the globalized and competitive scenario, dairy producers grapple with challenges related to production costs, milk prices, climate change, milk quality, new technologies, labor shortages, dairy product imports, and overall productivity.

In this context, the CB system has been an alternative for dairy producers to boost production and improve milk quality, achieving better financial returns and greater animal welfare.

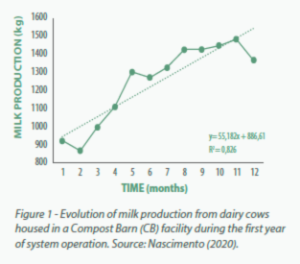

To showcase the progression in milk production among small-scale producers, Professor Flávio Alves Damasceno and his student João Antônio Costa do Nascimento conducted a study at the Federal University of Lavras (UFLA). The study involved 70 dairy cows that had previously been pasture-raised and were subsequently shifted to the Compost Barn (CB) system.

In the initial year of housing, there was a notable 48% surge in total milk production, indicating an average per-animal increase of 23.3% (see Figure 1). In this instance, the heightened productivity of confined cows within the CB system is ascribed to the environmental conditions of their housing.

A noteworthy point to bear in mind regarding lactating cows raised in pastures is that they yield one liter less of milk for every kilometer traveled daily. For instance, if pasture-raised animals cover a distance of 4 km each day—2 km to reach the milking parlor and 2 km to return to pastures—transitioning to a CB system could potentially result in an extra 2 liters of milk production per day. Additionally, animal fatigue poses a constraint on feed intake.

Quality of Milk from Dairy Cows in the Compost Barn System

Dairy cattle housed in confinement systems have better udder health due to reduced exposure to climatic factors faced in the field. High soil humidity during rainy periods is one of the main causes of mastitis in pasture-raised dairy herds.

Therefore, when the CB bedding is properly managed, animals confined in the compost barn system are less likely to have bedding material adhering to their udders, favoring better milk quality and reducing milk discard.

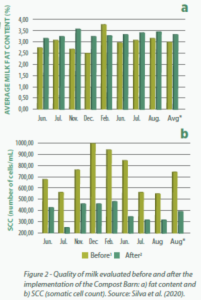

In a separate study evaluating milk quality before and after the introduction of the Compost Barn (CB) system, it was noted that post-implementation, there was an 11.3% rise in milk fat content compared to the period under the pasture system (Figure 2a).

In the CB system, animals experience improved comfort and welfare, contributing to better feeding conditions. Thus, when animals are subjected to thermal stress, they reduce food consumption, aiming to decrease metabolic heat production.

![]()

Adequate food intake delivers a greater quantity of fibers to the animals’ bodies, promoting rumination activity. This, in turn, improves nutrient absorption and contributes to a higher concentration of fat in the milk.

Furthermore, comparing the averages of the two periods, it is evident that after the CB installation, there was a 46.8% reduction in somatic cell count (SCC) (Figure 2b).

A well-managed CB breeding system can contribute to reduced udder contamination and, consequently, a decrease in mastitis cases, also contributing to the improvement in milk quality.

Conclusions

![]() Dairy producers from various countries have discussed various concepts about CB facilities in specialized technical journals, forums, and conferences, indicating significant interest in this new animal housing system.

Dairy producers from various countries have discussed various concepts about CB facilities in specialized technical journals, forums, and conferences, indicating significant interest in this new animal housing system.

Despite the increasing popularity of the CB system in Brazil, scientific knowledge about this system is limited, requiring integrated studies to assist in the decision-making and planning process. These studies should correlate technical and economic impacts on nutrition, production, and milk quality to better understand the CB’s influence on farm results.

Overall, there is a noted contribution of the Compost Barn (CB) to enhancing thermal comfort and milk quality, resulting in heightened animal productivity due to the system’s advantages. Nevertheless, these enhanced outcomes are predominantly evident in highly specialized dairy herds possessing genetic potential that facilitates increased daily production in response to the CB.

Authors: Flávio Alves Damasceno¹ Gustavo Ferreira Almeida²

¹Professor and Researcher in Compost Barn – Federal University of Lavras (UFLA) ²Dairy Cattle Nutritionist at Gadileite

[/register]

You may also like to read: “TMR silage: possibilities and limitations for on farm application”

Subscribe now to the technical magazine of animal nutrition

AUTHORS

Nutritional Interventions to Improve Fertility in Male Broiler Breeders

Edgar Oviedo

The Use of Organic Acids in Poultry: A Natural Path to Health and Productivity

M. Naeem

Synergistic Benefits of Prebiotics and Probiotics in Poultry, Swine, and Cattle

Gustavo Adolfo Quintana-Ospina

Hybrid Rye Potential in Laying Hen Feed Rations

Gwendolyn Jones

A day in the life of phosphorus in pigs: Part I

Rafael Duran Giménez-Rico

Use of enzymes in diets for ruminants

Braulio de la Calle Campos

Minerals and Hoof Health in the Pregnant Sow

Juan Gabriel Espino

Impact of Oxidized Fats on Swine Reproduction and Offspring

Maria Alejandra Perez Alvarado