10 Oct 2022

10 Oct 2022

Nitrogen (N) is the building block for proteins found in feed and fodder. Protein is usually the most expensive component used in purchased feed for dairy cattle rations.

Nitrogen has drawn attention as a significant component of nutritional management plans on dairy farms as well as due to concerns regarding ammonia emissions.

It is worth recalling that dairy cows do not require protein per se. What they actually need are available amino acids within the small intestine for their uptake and use to support tissue growth and milk production.

N use in dairy cattle basically consists of two elements:

Although all foods contain N, the amounts in which it found in different feeds, its availability and how it is used by dairy cows can be highly variable. Forage analysis laboratories determine the amount of N in analyzed samples and multiply this value by 6.25 to obtain the crude protein (CP) value.

|

Calculation example: Alfalfa silage = 3% N * 6.25 = 18.75% CP (both on a DM basis) |

Although different feeds may have the same CP value, the nutritional value for the dairy cow will be different depending on the feed. Let’s look at the following examples:

[register] Although these feeds have the same CP levels, we wouldn’t expect the same N utilization levels and milk production. If 2kg of raw soybeans/cow/day are being fed to a dairy cow producing 36kg of milk, and they are replaced BY 2kg of roasted soybeans, this would represent a 1% increase in predicted protein-based milk production.

What is the reason behind this?

– True protein = Refers to N from feed, which is found in amino acids. Some examples are: albumins, globulins and amino acids. These feeds will vary in regards to the speed and degree of degradation that they undergo in the rumen.

– Non-Protein Nitrogen (NPN) = This is the N found in simple compounds such as ammonia or urea (not as amino acids). These are considered to be quickly available in the rumen.

The aforementioned components are an approximation at defining N sources. However, the true protein component requires a better definition that establishes its use in ration formulation and in evaluation programs. This is most commonly done as follows:

Part of the N found in feed entering the rumen will degrade to compounds such as peptides, amino acids or ammonia. The main degradation mechanism within the rumen is microbial proteolysis. Feed solubility, structure and particle size will influence the total volume that is degraded.There is always a N portion of the feed entering the rumen that remains undegraded (RUP).

| RDP does not fully decompose and turns into ammonia at the same rate. Van Soest (1994) established a system to help define N sub-fractions. Allowing a better characterization of N availability and its use in dairy cow feed. This system includes the following fractions: A – These are mainly NNPs, amino acids and peptides which are “instantly” available within the rumen. B1: This fraction has a rapid ruminal degradation rate. B2: This fraction has a variable degradation rate within the rumen. B3: This fraction has a slow ruminal degradation rate. C: This fraction is not degraded within the rumen. However, it is not available nor digested within the small intestine and it is eliminated in the feces. |

This approach contributes to a better description of N use within the rumen. Which in turn helps to improve the efficiency of N use in feed.

Microbial protein (MCP) is produced in the rumen by microorganisms. The key factors that determine the amount of MCP synthesized are: the amount of available ammonia in the rumen and the supply of fermentable carbohydrates to provide an energy source.

The availability of peptides can also stimulate MCP production by certain rumen microorganisms. The NRC (2001) establishes MCP production as 13% of the TDN (total digestible nutrients) available in the rumen.

Microbial protein can provide 50 to 80% of the amino acids needed within the intestine by dairy cows. Optimized MCP production contributes to increasing the efficiency of nitrogen use in the cow as well as to control feed costs.

The benefits of MCP are:

There are 2 systems that are used to evaluate and balance the rations of dairy cows based on protein, which are:

The CP system is the most commonly used system, as it is easy to use and there is a lot of information regarding feed composition and animals’ nutritional requirements. This system assumes that all the N in different feeds is similar in regards to its use and nutritional value for ruminants. The NRC (2001) determined that CP was a poor predictor of milk production.

Nutritionists have modified the CP system in order to better meet their needs . They have added SP (soluble protein), RDP and RUP as additional factors to consider when using CP as a base in diet formulation.

The NRC (2001) has suggested moving to a PM system in order improve protein definition and refine its formulation and use. This system fits the biology of the cow more accordingly.

The challenge behind it, is that this system is non-tabular and requires the use of software to calculate both PM requirements and the PM provided by the ingredients as well as by the MCP.

Nonetheless, the industry is shifting towards an MP approach. This system should provide an opportunity to improve the efficiency of protein use in dairy cattle.

This system will also contribute to reducing N excretion into the environment as well as reducing potential ammonia emissions.

It is important to realize that dairy cows are a dynamic system and not static. This means that the actual value of a feed nitrogen source will vary depending on several factors. These include:

This scenario is similar to the difference found in the energy value of feed due to changes in dry matter intake (DMI) and passage rates:

![]()

Dairy cows with higher DMI levels have a higher passage rate and lower feed energy values. That is why feed energy values are deducted based on DMI levels and milk production (NRC, 2001).

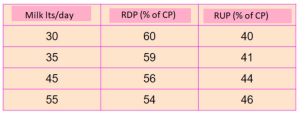

The NRC (2001) computer model was used to determine the RDP and RUPs for soybean meal used in the ration of dairy cows. The base ration was for a cow that produced 30kg of milk and contained 2kg of soybean meal. This ration was then evaluated for cows producing 35, 45 or 55kg of milk.

The ingredients of the ration were all kept in the same proportion, but the DMI of the total ration was adjusted using the intakes provided by the NRC program. The RDP and RUP values for soybean meal in this ration were:

The reason behind the higher RUP value in higher production cows is due to the shorter amount of time that soybean meal remains within the rumen. Therefore, there is less time for N degradation and proteolysis.

This example also highlights the challenge of using tabular values to describe ingredients’ RDP and RUP fractions.

Nitrogen is the most expensive component in feed costs on most dairy farms. Formulation programs that incorporate the concepts of feed fractions and variable feed contributions in animals provide an opportunity to adjust nutrition as well as improving nutrient use efficiency.

This will also reduce nutrient excretion into the environment while obtaining revenues that surpass feed costs.

Source: L.E. Chase, Cornell University

[/register]

Subscribe now to the technical magazine of animal nutrition

AUTHORS

Nutritional Interventions to Improve Fertility in Male Broiler Breeders

Edgar Oviedo

The Use of Organic Acids in Poultry: A Natural Path to Health and Productivity

M. Naeem

Synergistic Benefits of Prebiotics and Probiotics in Poultry, Swine, and Cattle

Gustavo Adolfo Quintana-Ospina

Hybrid Rye Potential in Laying Hen Feed Rations

Gwendolyn Jones

A day in the life of phosphorus in pigs: Part I

Rafael Duran Giménez-Rico

Use of enzymes in diets for ruminants

Braulio de la Calle Campos

Minerals and Hoof Health in the Pregnant Sow

Juan Gabriel Espino

Impact of Oxidized Fats on Swine Reproduction and Offspring

Maria Alejandra Perez Alvarado