Palm kernel cake and meal(Raw material sheet)

Definition & classification

Palm kernel cake and palm kernel meal are by-products obtained of the oil extraction from the seed of African oil palm (Elaeis guineensis). A species variety which is mainly grown in tropical areas of both Africa and Asia.

Almost 80% of the world’s palm oil production originates from Indonesia and Malaysia. Other producing countries are: Nigeria, Thailand, Colombia, Papua New Guinea and Ecuador (FAO, 2012). However, the production of the aforementioned countries is significantly lower compared to the major producers. Europe and New Zealand are major importers of palm kernel meal and cake. In Malaysia and Indonesia, palm oil production takes place in large areas which are generally run by private companies. However, in other regions, such as in West African countries, its production is divided among small farmers.

In 2008, the Roundtable on Sustainable Palm Oil (RSPO) developed a voluntary certification system to ensure sustainable production.

Recent studies indicate that this certification allows to reduce greenhouse gas emissions by 35% compared to non-certified productions(Schmidt & De Rosa, 2020). Thus, reducing the environmental impacts of this industry.

Palm oil production is generally associated with deforestation and loss of biodiversity. This is especially true in Southeast Asia, due to the type of production system used in this region. These aspects have been highly criticized by the public, especially in Europe, the main importer of these raw materials.

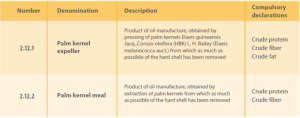

The “Catalogue of raw materials” (Regulation (EU) 68/2013) classifies palm kernel cake and meal for animal feed, in the following section: “2. Oil seeds, oleaginous fruits and their derived products” (Table 1).

Table 1. Classification of palm kernel according to the Catalogue of Raw Materials (Regulation (EU) 68/2013).

It is mandatory to declare the protein and fiber content in the cake, as well as its fat content.

Procurement process

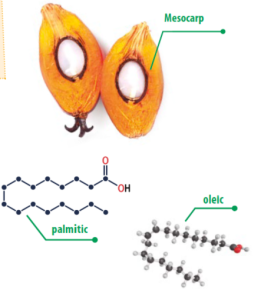

The oil palm fruit has: a fine epicarp, a fleshy, oily mesocarp and a hard endocarp containing an endosperm (kernel, seed). Palm oil is extracted from the mesocarp and is rich in long-chain fatty acids such as palmitic and oleic acids.

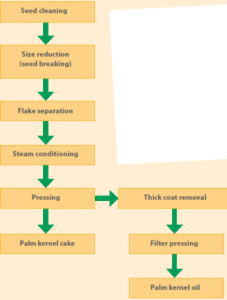

Figure 1. Procurement process for palm kernel oil (Poku, 2002).

The three basic steps followed in the mechanical extraction of palm kernel oil are:

- steam pretreatment of the seed

- pressing of the seed,

- rinsing and filtering of the oil (Figure 1, Poku, 2002).

After this mechanical extraction, some of the specialized processing plants apply solvent degreasing agents.

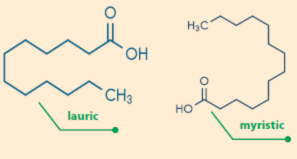

In a second phase, the seed is fragmented in order to release the endosperm. Seeds are then usually derived to other processing units where they are subjected to pressure or solvent treatments to extract palm kernel oil, which is rich in medium-chain fatty acids (lauric, myristic).

The kernels and meals derived from this process are intended for animal feed.

According to Pickard (2005), the yield of oil extraction from the nuts (seeds) of the oil palm is approximately 43%.

The remaining (57%) is palm kernel cake, which usually contains 35% pericarp and 65% fruit.

Chemical composition & nutritional value

Palm kernel cake and meal are by-products of oilseeds. However, these have significantly lower energy and protein values than other better-known oilseed derivatives such as: soybean, rapeseed or sunflower meal /cake.

This is due to the fact that it contains a lower proportion of protein (17-19%) and high fiber content (60-70% NDF), which is quite lignified.

Its remarkably high content of galactomannans, provide a certain insolubility to its fiber content. The fiber derives from the seed coating and its content is variable. Which leads to a high variability in regards to its nutritional value.

As with other raw materials:

- Cakes ( oil extraction through pressure) contain a higher fat content (8-9%), than meals (solvent oil extraction, 2-3%).

- Therefore,cakes can provide a higher energy value for animals.

Unlike with other oilseeds, the cake is used more often in animal feed, compared to the meal.

Table 2 shows the composition published by FEDNA for soybean, rapeseed and palm oils and soybean oleins and palm distillates. This table also shows the composition published by INRAE-CIRAD-AFZ.

With the exception of the FEDNA tables, other common feed tables such as the INRAE tables or the CVB tables do not provide the composition of industrial by-products derived from fats.

Table 2. Chemical composition (in dry matter) of palm kernel cake and flour.

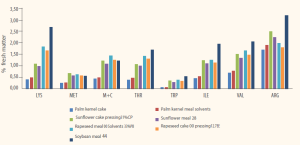

- The percentage of different amino acids (AA) is low compared to other oilseed by-products (Figure 2). However, the profile is similar to the protein found in sunflower and rapeseed cakes and meals.

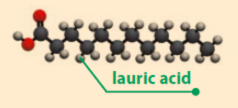

- The fatty acid content is logically higher in the case of cake compared to meal; highlighting its high content of lauric and myristic acid, which is characteristic of palm seed. It also possesses a high content of oleic acid.

Figure 2. Amino acid proportions found in the main oilseed meals and cakes used in animal feed (FEDNA, 2019).

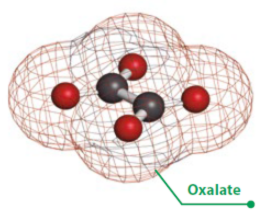

Palm kernel cake presents different antinutritional factors, such as: 0.40% tannic acid, 6.62 mg/g phosphorus phytin, 23.49 mg/g phytic acid and 5.13 mg/g oxalate. These factors affect the nutritional quality of palm kernel cake negatively(Akinyeye et al., 2011).

Use in animal feed

Palm by-products have traditionally been used in ruminant feed, due to their high fiber content. Palm kernel cake and meal are considered protein ingredients with low degradability both for their energy and protein content. Their fat content is also quite inert for rumen microorganisms.

Within highly producing areas such as Malaysia, dairy cow rations can contain up to 50% palm kernel cake, at the expense of fewer quantities of soybeans and corn without negative consequences on animal production and health.

In dairy breeds, inclusion levels of 15% have been considered to be safe for maintaining production and health levels in animals. These have even shown a tendency to increase the concentration of protein in milk(Carvalho et al., 2006).

In rabbit feed, these by-products are also valuable sources of fiber and protein and can meet the nutritional requirements of high-producing rabbits (de Blas et al., 2010).

In rabbit feed, these by-products are also valuable sources of fiber and protein and can meet the nutritional requirements of high-producing rabbits (de Blas et al., 2010).

In other monogastric species such as pigs and poultry, these ingredients have a low nutritional value. This is mainly due to their their high finer levels, as well as due to their low palatability.

Recommended inclusion levels in poultry range from 5-10% and in pigs from 15-25% (Wan Zahari et al., 2005; Zanu et al., 2012, respectively). However, these levels will depend on the quality of the cakes and meals being used.

In addition, recent studies indicate that the treatment of these raw materials with solid fermentation reduces the fiber content. Degrading the most complex carbohydrate fractions, which improves their nutritional value and allows higher levels of inclusion in broilers (10-15%; Azizi et al., 2021).

Other treatments such as hydrolysis with mannanases or the inclusion of mannanases in feed appear as promising strategies to help increase the nutritional value of these ingredients in monogastric feed (Jang et al., 2020; Sathitkowitchai et al., 2022).

It is also worth noting that these ingredients contain bioactive lipids, such as lauric acid, which may have antimicrobial effects. These are also a potential source of prebiotics which can benefit animal health.

Conclusions

- Palm kernel cake and meal are fibrous ingredients with good acceptance levels in ruminant production. These can also be used in pig feed but with certain limitations.

- Actions taken towards making palm oil production more sustainable and improving the nutritional value of these by-products, are key aspects to enhance the use of these raw materials in animal feed.

Source: This article was originally published in NutriNews Spain March 2023

You may also like to read: “Thermal treatment of raw materials used in ruminant diets- Part 1.”