20 Feb 2023

20 Feb 2023

Precise nutrition is essential for an efficient and sustainable production-Sustainability Series:

Editorial

This article starts a collection of documents to be published in the following issues of NutriNews International on methods and services available to the livestock industries, establishing specific sustainability parameters and technologies that contribute to their improvement. Sustainability indices are key indicators of how a company or production system is set to safely co-exist with the environment over a long-time while ensuring a balance between economic growth, the environment, and social well-being. Most strategies for better sustainability enhance productivity and improve company and brand acceptability among consumers.

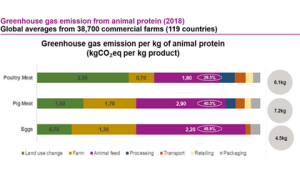

For example, thanks to genetic selection, better housing, management, and health control, poultry meat and egg production globally currently have the lowest greenhouse gas emissions (9.87 and 4.67 kg CO2eq, respectively) among all animal protein production. The CO2 equivalents (CO2eq) is the amount of CO2 that would have the same global warming potential when measured over a specified timescale, generally 100 years.

Greater efficiency in the live poultry production systems, processing, and marketing generally satisfy all aspects of sustainability. This means that everything we do in genetic selection, improving precision in nutrition, and environmental management may contribute to reducing carbon footprint, land, water, energy use, global warming, and pollution potential.

Broilers today need approximately 220 grams less feed and yield 74 grams more breast meat per kilogram of live weight than broilers produced in 2005. A 2.5 kg broiler eats 0.55 kg less feed than it used to 18 years ago. The carbon footprint of chickens ranges between 2.7 and 4.0 kg CO2e per kg of bonefree meat or between 1.5 and 3 kg CO2e per kg of eggs, depending on the production system. These values are considered below the threshold indicator to be considered green or friendly to the environment.

Producing feed is responsible for 70 to 80% of the total greenhouse gas emissions, land and energy use of producing poultry. In the past 15 years, a better feed conversion ratio has decreased the land used to produce feed ingredients by 37%, and 10% fewer broiler houses are needed. Energy use has decreased by 16%, and gas emission is 7%. Nitrate and phosphate excretion was minimized by 20%, and one liter less water is needed to produce the same 2.5 kg broiler today.

In this series, diverse companies will present their vision of how they can contribute to enhancing sustainability. How they can measure their impact and the potential benefits of using these technologies. In this first issue, Dr. Fernanda Casto and Dr. Nei Arruda from Evonik present one example of their work in this area.

Evonik’s vision for sustainability

In November 2022, the world’s population reached 8 billion people; according to the projections, it is expected to reach 9 billion before 2040, according to the United Nations report. This exponential increase in population puts pressure to improve the productivity of crops and animal protein and preserve natural resources.

Animal production, in particular, is becoming increasingly committed to sustainable practices, focusing on feeding billions of people while reducing its ecological footprint. In this regard, the ecological footprint, a concept developed by researchers from the University of British Columbia in 1990, measures how fast we consume resources and generate waste compared to how fast nature can absorb our waste and generate resources.

Furthermore, ESG (Environmental, Social, and Governance), a framework that helps stakeholders understand how an organization manages risks and opportunities regarding sustainability, has shown tremendous engagement worldwide. Many companies have already committed to sustainable practices due to market pressure, especially consumers.

The financial market has played a vital role in accelerating ESG implementation. Credit lines and investments already require companies to be framed with ESG practices and to report sustainable efforts. The Coller FAIRR Protein Producer Index (2020), which assesses 60 of the largest companies in the animal protein market, reported the ten critical risk and opportunity factors (Figure 1) related to the sustainable development goals (SDG). This resource is used by various stakeholders, including companies, investors, and experts. We have gone from an environmental to a financial asset. Thereby, in future discussions, sustainability is a green issue and a governance and social concern.

Figure 1. The ten risk and opportunity issues in the animal protein market

Climate change was one of the most discussed topics during the 2022 United Nations Climate Change Conference (COP27, Egypt). However, global emission levels remain at record highs, and the world is on track to raise its temperature by more than 2°C. In 2020, the global agri-food systems emissions were 16 billion tons of carbon dioxide equivalent (Gt CO2eq), an increase of 9% since 2000 (FAO, 2022).

The livestock sector contributes to 31% of total global greenhouse gas emissions (GHG). In comparison, feed grains and land use for livestock contribute 6 and 16%, respectively (Poore and Nemecek, 2018). More specifically, poultry and swine production contribute to GHG emissions by approximately 2 and 3%, respectively (CIEL, 2022; UK National Inventory, 2019).

The agribusiness leaders are concerned about climate change and are aware of the importance of decarbonization, leading to the incorporation of sustainable practices into the business model. Animal feeding has had a significant contribution to GHG emissions. Data from research presented by “Our World in Data” (figure 2) showed that the animal diet contributed 30 to 50% of the total GHG emissions generated by producing 1 kg of meat or eggs. However, since most of the land use change comes from feed ingredient production, it is not unreasonable to assume that the GHG emission from the animal diet is even higher (70 to 80% of total emissions).

Figure 2. Greenhouse gas emissions at each production stage per kilogram of meat or eggs (Adapted from Poore and Nemecek, 2018). Data represents the global median greenhouse gas emissions of food products based on a large meta-analysis of food production covering 38,700 commercially viable farms in 119 countries.

Life Cycle Assessment (LCA) has been the primary analysis supported by Non-Governmental Organizations and the industry for sustainability assessment of livestock production. The LCA systematically analyzes environmental impact throughout the entire life cycle of a product, material, process, or other measurable activity. It helps to make this impact concrete and actionable through scientific quantification. However, according to international standards, the complete LCA can be very complex and expensive, with little application daily.

In recent years, several LCA tools or databases have been developed to help calculate the environmental impact of animal diets in a simplified and effective way. These resources, however, focus mainly on GHG emissions and, related to that, on deforestation. Therefore, sustainability services are the leading solution that can be tailored specifically to the market needs while providing additional environmental parameters, such as Acidification Potential (AP); Eutrophication Potential (EP); Global warming potential (GWP); Land-use change (LUC); and water footprint. This way, livestock producers can access information on feed ingredients’ environmental impact, calculate the ecological profiles of compound feed, and identify diets with the lowest environmental impact.

Precision nutrition and its consequent improvement in production efficiency can improve the profitability of one`s operations by reducing feed costs and environmental impact. By formulating diets that meet the nutrient requirements consistently throughout production, without excess nutrients, it is possible to minimize the burden of environmental systems.

Nowadays, an extensive array of feed additives, alternative ingredients, services, requirement recommendations, and nutritional strategies are available to improve the sustainability of an operation. Some of these resources can help improve nutrient utilization and poultry feed efficiency (feed volume reduction), weight gain, reduce mortality, and improve overall health. Others, like Near-infrared (NIR) equipment and equations, can support precision feeding through reliable and fast assessment of the nutritional levels of feed ingredients for a better formulation.

Regarding nutritional strategies, the reduction in crude protein (CP) with supplementation of crystalline amino acids and its impacts on performance and the environment have been studied for many years. However, the practical application of this concept could only be possible due to the availability of supplemental amino acids in a cost-effective way.

Several benefits associated with the reduction of CP have been demonstrated, such as formulation flexibility, reduction in nitrogen excretion and ammonia formation, lower phosphorus emissions, promotion of better littler quality and lower food pad lesions, improving welfare, support of good intestinal health by reducing nitrogen substrate for pathogens proliferation, and reduction of water/feed ratio.

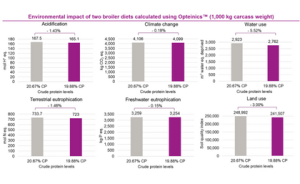

Calculating the ecological footprint has become an increasingly sought-after practice. An LCA was conducted using the software Opteinics™ to evaluate the environmental impact of different crude protein levels of two broiler diets from a study conducted at Zamorano University, Honduras (Machado et al., 2022). A standard corn-soybean meal-based diet containing, on average, 20.67% CP was compared to a 19.88% CP diet supplemented with DL-Methionine, L-Threonine, and L-Valine. Therefore, a cradle-to-slaughterhouse LCA simulation covered three phases: 1. Feed Production 2. Animal Farming 3. Meat Processing (Figure 3). The Global Feed LCA Institute (GFLI, 2.0 ReCiPe, and EF3 method) database was used for the ingredients’ environmental impacts.

Figure 3. System boundaries (modified diagram from BASF)

The results showed a reduction of 1.43% in acidification, 0.18% in climate change, 1.46% in terrestrial eutrophication, 0.15% in freshwater eutrophication, 3% in land use, and 5.52% in water use per 1,000 kg of carcass weight when the CP was reduced while maintaining statistically similar performance (figure 4).

Figure 4. The environmental impact of diets with different crude protein levels in broiler production was calculated by Opteinics™, a BASF software licensed to Evonik.

Additionally, a study by Lemme et al. (2019) demonstrated that the CP level could be reduced from 20.4 to 18.7% (average protein content across all phases) without a detrimental impact on the performance of broilers from 1-40 days when amino acids are supplemented. On average, the authors have also seen a 13.6% reduction of N-excretion per %-point dietary CP reduction, with a stepwise improvement in N-utilization with a reduction in CP levels.

When applying the Coller FAIRR report to the strategies above, it is possible to see that the industry has been working on its points for quite some time. For example, 1) the use of additives, such as probiotics, prebiotics, and organic acids in antibiotic-free production support SDG 3 (good health and well-being); 2) the pursuit of feed efficiency improvement support SDG 2 (Zero Hunger and sustainable agriculture); 3) precise nutrition can support GHG emission reduction (SDG 13 – climate change), food safety (SDG 2 and 3), water consumption reduction (SDG 6 – clear water and sanitation and 15 – life on land), and better use of raw material with lower deforestation (SDG 14 – life below water and SDG 15).

However, transparency of the sustainability performance in animal production in a clear way, as required by retailers and consumers, is still a challenge for the producers. Therefore, more straightforward solutions that can be used routinely and quantitatively to measure the environmental impact of an operation, as well as certifications for sustainable actions, are of great interest to the industry.

Undeniably, it is not only possible but also necessary to obtain a more sustainable animal production system. Improving the selection of feed ingredients, evaluating its nutritional profile, and using feed additives and strategies make it possible to optimize production costs while reducing environmental emissions and resource waste.

Bibliographical References:

UNITED NATIONS (UN), 2022. https://www.un.org/en/dayof8billion#:~:text=On%2015%20November%202022%2C%20the,nutrition%2C%20personal%20hygiene%20and%20medicine

Subscribe now to the technical magazine of animal nutrition

AUTHORS

Nutritional Interventions to Improve Fertility in Male Broiler Breeders

Edgar O. Oviedo Rondón

The Use of Organic Acids in Poultry: A Natural Path to Health and Productivity

M. Naeem

Synergistic Benefits of Prebiotics and Probiotics in Poultry, Swine, and Cattle

Gustavo Adolfo Quintana-Ospina

Hybrid Rye Potential in Laying Hen Feed Rations

Gwendolyn Jones

A day in the life of phosphorus in pigs: Part I

Rafael Duran Giménez-Rico

Use of enzymes in diets for ruminants

Braulio de la Calle Campos

Minerals and Hoof Health in the Pregnant Sow

Juan Gabriel Espino

Impact of Oxidized Fats on Swine Reproduction and Offspring

Maria Alejandra Perez Alvarado