26 Oct 2022

26 Oct 2022

Soy processing is useful and necessary for:

![]() destroy or remove undesirable components,

destroy or remove undesirable components,

![]() make nutrients more available,

make nutrients more available,

![]() Improve palatability.

Improve palatability.

Moist heat treatment is particularly effective in reducing trypsin inhibitor activity.

With current manufacturing processes, the residual trypsin inhibitory activity in soybean protein products is approximately 5 to 20% of the original inhibitory activity found in raw soybeans.

The amount of heat required to destroy trypsin inhibitors and other hemagglutinins found in raw soybeans depends on the time of exposure. Therefore, high temperatures in shorter exposure periods are just as effective as lower temperatures for longer periods.

Whole soybeans can replace soybean meal in pig and poultry diets with similar yields.

The decision on which soy product to use should be based on the composition, availability, and costs of the product.

![]() Soybean meal

Soybean meal

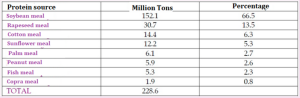

Soybean meal is the most common source of protein in poultry and pig feeds (Table 1). This popularity stems from its nutrient content and relative absence of anti-nutritional factors.

Table 1. Global consumption of meal or flour as a source of protein for domestic animals.

Modified from Dourado et.al 2011 Modified from Dourado et.al 2011 |

The quality of soybean meal is the result of many factors, including the variety, origin, and storage of the beans.

The multiple processing steps that are carried out from the moment the bean is received, affect the quality of the end products like: flour and oil.

The heat treatment of flour is essential to optimize its protein quality. Variables such as: humidity, temperature and time are interrelated and are essential for achieving adequate cooking conditions.

![]()

Many in vitro tests designed to measure protein quality in soy have been proposed and evaluated. Simple crude protein or amino acid assays provide information about the protein, but do not provide useful information about the quality of the protein.

That is why analyses of trypsin inhibitors, urease activity, protein solubility in potassium hydroxide, protein solubility in water and dye binding methods have been used to assess protein quality.

[register]

| Inadequate heating can lead to incomplete destruction of anti-nutritional factors, which can have a detrimental impact on animal performance. On the other hand excess heating reduces amino acid availability due to the Maillard reaction. This is especially true for lysine. |

Although processed soybeans must be tested periodically for urease or trypsin inhibitor levels, a simple and practical test is to simply taste the beans.

Under-heated beans have a characteristic “nutty” flavor, while overheated beans have a much darker color and a burnt taste.

The problem with overheating is the potential destruction of lysine and other heat-sensitive amino acids.

The most widely adopted, most economical and fastest method is the measurement of urease activity (urease test or urease index). Urease enzyme levels are used as an indicator of trypsin inhibitory activity.

Urease is much easier and cheaper to measure than trypsin inhibition, and both molecules have similar heat sensitivity characteristics.

Two analytical methods for urease testing are described here:

However, the urease index is not useful in determining excessive heat treatment as further heating has no effect on the this type of index.

The KOH protein solubility test is based on the solubility of soybean proteins in a dilute solution of potassium hydroxide.

The procedure involves the incubation of a sample in a 0.2% KOH solution for 20 min at room temperature.

After this incubation, the sample is centrifuged and the supernatant is analyzed to determine protein concentration.

The solubility of the protein, expressed as a percentage, is calculated by dividing the protein content extracted from the KOH solution by the protein content of the original soybean sample.

KOH protein solubility is a better indicator of soybean over processing than its under processing.

Table 2 shows the levels of urease activity and protein solubility in potassium hydroxide acceptable in most soybean processes.

Table 2. Accepted relationship between the degree of soybean processing for urease activity and protein solubility in potassium hydroxide.

|

|

The nitrogen solubility index (NSI) is another method that can be used to determine protein quality.

Nitrogen is extracted from ground flour by placing approximately 1.5 g in a 200 ml beaker and adding 75 ml of 0.5% KOH. The sample is shaken for 20 minutes at 120 rpm.

It is a more consistent and sensitive indicator for monitoring both soybean heating and overheating.

![]() Soybean shell

Soybean shell

Soybean husks, due to their high fiber content, are known to be poorly digested by non-ruminant animals. However, recent studies suggest that husks have potential as an alternative feed ingredient for pigs and poultry.

Soybean shells can be included up to 10% and 12% for the diets of growing or finishing pigs, respectively. Replacing wheat bran based on weight without adverse effects on diet palatability nor on animal performance (Chee et al. , 2005).

Currently, it is very common to use soybeans in feed restriction and welfare programs for breeders and laying hens.

![]() Soybean protein isolates

Soybean protein isolates

Soybean concentrate is obtained by removing most of the oil and non-protein water-soluble constituents from healthy, clean and selected shelled seeds.

Both soybean protein concentrates and isolates have the potential to be used in poultry diets as a source of protein and amino acids.

![]() Soybean oil

Soybean oil

Soybean oil is a highly concentrated source of dietary energy. Its caloric value is the main reason for its greater use. As well as due to its excellent nutritional qualities and wide availability.

Gaiotto et al., (2000) evaluated the performance of broilers fed with diets containing 4% supplemental fat from these sources:

The superiority of soybean oil relative to other fat sources was confirmed in their experimental trials.

Storage and genetic variation are factors that can alter the nutritional composition of soybeans.

Narayan et al., (1988) found that: moisture content, fat, water-soluble nitrogen (WSN), nitrogen solubility index (NSI), sugars, trypsin inhibitory activity, available lysine, pigments and seeds’ lipoxygenase activity, decreased during storage. On the other hand, non-protein nitrogen (NPN), the degree of browning, free fatty acids'(FFA) content and the peroxide index increased during storage.

Conclusions

The benefits of the inclusion of soybeans and their derived products for poultry and pig nutrition are evident. However, is very important to understand which factors affect the composition of the ingredients so that they can be included in adequate quantities without negatively impacting animal performance.

Source: This article was originally published as a content in spanish on Nutrinews LATAM

[/register]

Subscribe now to the technical magazine of animal nutrition

AUTHORS

Nutritional Interventions to Improve Fertility in Male Broiler Breeders

Edgar Oviedo

The Use of Organic Acids in Poultry: A Natural Path to Health and Productivity

M. Naeem

Synergistic Benefits of Prebiotics and Probiotics in Poultry, Swine, and Cattle

Gustavo Adolfo Quintana-Ospina

Hybrid Rye Potential in Laying Hen Feed Rations

Gwendolyn Jones

A day in the life of phosphorus in pigs: Part I

Rafael Duran Giménez-Rico

Use of enzymes in diets for ruminants

Braulio de la Calle Campos

Minerals and Hoof Health in the Pregnant Sow

Juan Gabriel Espino

Impact of Oxidized Fats on Swine Reproduction and Offspring

Maria Alejandra Perez Alvarado