In this article, we will continue discussing the effects of corn harvest conditions and drying temperature on the variability of corn in feed processing for poultry and swine diets, and its energy and nutritional value for growing pigs and broilers.

It is important to remember that corn kernel hardness is an important seed genetic characteristic affected by agronomic and weather conditions. Corn vitreousness is a measurement of kernel hardness that refers to the ratio of vitreous (hard) to floury (soft) endosperm. NIRS can be used to measure it. In the previous article, we discussed some of the impacts of corn vitreousness in phytate content, nutritional value, protein solubility, and how it may affect the particle size post-grinding.

Variability in feed processing

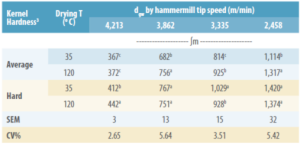

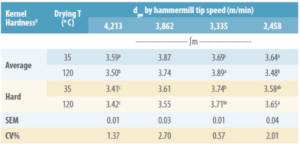

In a subsequent experiment, we evaluated the effects of drying temperature (35 or 120°C) in two yellow-dent corn hybrids with different kernel hardness (average and hard) on the geometric mean diameter (dgw) and standard deviation by weight (Sgw) when hammermilled, and pellet quality measured as pellet durability index (PDI).

This time, the corn vitreousness was 60.59% for the average variety and 62.83% for the hard variety. Meanwhile, the protein solubility index or Promatest values were 37.27% and 34.42% for the average and hard corn varieties, respectively.

In grinding in a hammer mill, four different settings combinations of tip speeds (4,213, 3,862, 3,335, and 2,458 m/min) and screen of 8/64′′, 3.18 mm (8−8); 20/64′′, 7.94 mm (20−20); 24/64′′, 9.53 mm (24−24); and 24/64′′, 9.53 mm (24−24), respectively, were used to target four dgw (400, 700, 925, and 1,250 μm).

After grinding, the 400 and 700 µm corn were included in broiler and sow diets to assess the impact of these treatments on the pellet durability index. Grinding and pelleting data were analyzed using a 2 × 2 factorial arrangement of two corn varieties and two drying temperatures in a randomized complete block design with blocks by grinding or pelleting event.

The average hardness corn variety generally had the lowest dgw (Table 1). The hard corn variety had the biggest dgw when kernels were dried at 35oC, and the tip speed setting was 3,335 m/min. Drying at 120oC increased dgw for the average hardness corn variety when the target particle sizes were 700, 925, and 1,250 μm, but caused no increase in dgw at the lowest target particle size. In contrast, the dgw of hard corn variety was not affected by drying temperature when ground to target 700 and 1,250 μm and increased at 400 μm with the high drying temperature.

Table 1. Effect of the interaction (P<0.001) between corn kernel hardness and drying temperature on the particle size 1 geometric mean diameter (dgw) while grinding in a hammermill2 at different settings.

Values are means of 5 replicates per treatment combination. a-c Means in a column not sharing a common superscript are significantly different (P < 0.05) by Student’s t or Tukey’s HSD test. 1 Particle size analysis was determined using the ASAE S319.3 method (ASAE, 2003). 2 Hammermill Model 1522, Roskamp Champion, Waterloo, IA) equipped with two #8, 20, 24, and 24 screens, respectively. 3 Vitreousness: 60.59 % (DeKalb® 6357: Average) and 62.83 % (DeKalb® 6869: Hard) analyzed by NIRS (AB Vista, Plantation, FL). Source: Cabañas-Ojeda et al., 2023 Anim. Feed Sci. Tech 304, 115744.

The average hardness corn variety had higher Sgw, especially when dried at 35oC (Table 2). Higher particle uniformity (lower Sgw) was observed with the hard corn variety. Corn breaks differently depending on the force applied, but in all conditions, the kernel hardness and drying temperature affected the grinding results.

Table 2. Effect of the interaction (P<0.001) of corn kernel hardness and drying temperature on the particle size1 distribution expressed as geometric standard deviation (Sgw) while grinding in a hammermill2 at different settings.

Values are means of 5 replicates per treatment combination. a-c Means in a column not sharing a common superscript are significantly different (P < 0.05) by Student’s t or Tukey’s HSD test. 1 Particle size analysis was determined using the ASAE S319.3 method (ASAE, 2003). 2 Hammermill Model 1522, Roskamp Champion, Waterloo, IA) equipped with two #8, 20, 24, and 24 screens, respectively. 3 Vitreousness: 60.59 % (DeKalb® 6357: Average) and 62.83 % (DeKalb® 6869: Hard) analyzed by NIRS (AB Vista, Plantation, FL). Source: Cabañas-Ojeda et al., 2023 Anim. Feed Sci. Tech 304, 115744.

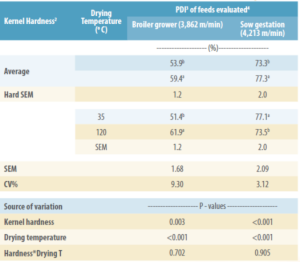

After pelleting, diets containing the hard corn variety presented better PDI than diets with the average kernel hardness variety (Table 3). Better broiler feed PDI was observed with corn dried at 120°C than at 35°C. However, this effect was the opposite when grinding at a lower particle size target for sow gestation diets. Grinding at a smaller size increases damaged starch.

Table 3. Effect of corn kernel hardness and grain drying temperature on pellet durability index (PDI) of broiler grower and sow gestation diets manufactured 1 with hammermilled ground corn at 3,862 and 4,213 m/min tip speeds, respectively.

a-b Means in a column not sharing a common superscript are significantly different (P < 0.05) by Student’s t or Tukey’s test. 1 Conditioning standard time of 30 seconds. Conditioning Temp: Grower: 85°C, Gestation: 82°C. Production rate: Grower: 16.55 lbs/30 sec, Gestation: 21.20 lbs/30 sec. Hot Pellet Temp: Grower: 83.9°C, Gestation: 85.8°C. 2 Vitreousness: 60.59 % (DeKalb® 6357: Average) and 62.83 % (DeKalb® 6869: Hard) analyzed by NIRS (AB Vista, Plantation, FL). 3 Pellet Durability Index was determined using an NHP100 pellet tester set to a 30-second interval (Holmen method). 4 Broiler diets contained 575 and 822 g/kg of corn and 4.5 and 1.0 g/kg of poultry fat for broiler grower and swine gestation diets, respectively. One basal diet was used for each dietary phase with soybean meal, distillers dried grains with solubles, and the only ingredient that changed was corn, according to the treatments described. Source: Cabañas-Ojeda et al., 2023 Anim. Feed Sci. Tech 304, 115744.

The particle size distribution and damaged starch of corn affected PDI. Higher corn drying temperature affected dgw and Sgw differently depending on corn variety and improved PDI in broiler diets, while 35°C drying temperature improved PDI in sow diets.

These results confirmed our previous observations that particle size and distribution vary according to kernel hardness and drying temperature. However, this time, the harvest occurred at lower kernel moisture, which could affect breakability.

Variability in corn nutrient value for pigs

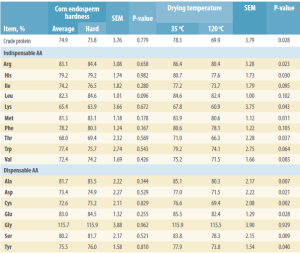

The digestibility of energy and nutrients of corn ground at 4,213 m/min of tip speed was evaluated by Dr. Hans Stein’s lab at the University of Illinois. The ileal digestibility of starch and amino acids (AA) and the apparent total tract digestibility of gross energy and total dietary fiber were estimated for growing pigs.

Results indicated (Table 4) that endosperm hardness did not influence the apparent ileal digestibility of starch or standardized ileal digestibility (SID) of AA in pigs. However, values for SID of most AA in corn dried at 120 °C were less than in corn dried at 35 °C. Hard endosperm corn (3,553 kcal/kg) also had greater apparent total tract digestibility of gross energy and total dietary fiber than corn with average endosperm hardness (3,403 kcal/kg), but drying temperature did not influence energy digestibility.

Table 4. Standardized ileal digestibility (SID) of crude protein (CP) and amino acids (AA) of corn varying in kernel hardness and drying temperature post-harvest1,2,3

1Data are least squares means of 20 observations per treatment. 2Values for SID were calculated by correcting the values for AID for basal ileal endogenous losses. Basal ileal endogenous losses were determined (g/kg of DMI) as CP, 23.71; Arg, 0.82; His, 0.30; Ile, 0.56; Leu, 0.81; Lys, 1.17; Met, 0.16; Phe, 0.50; Thr, 0.85; Trp, 0.14; Val, 0.68; Ala, 1.13; Asp, 1.32; Cys, 0.30; Glu, 1.69; Gly, 2.76; Ser, 0.80; and Tyr, 0.44. 3Corn source × drying temperature effects were not significant; therefore, only main effects are indicated. Source: Espinosa et al., 2023 J. Anim. Sci. 101, skad124.

Further research is needed to determine the optimum drying temperature and corn variety to maximize the nutritional value of corn. The main factor in the variability of the results of corn reported in the literature could be the moisture at the moment of harvest and the interaction it has with the drying temperature.

![]()

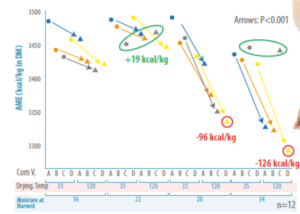

In a recent experiment, we observed this interaction effect. In Figure 1, we can observe the significant effect of higher drying temperature (120 oC) reducing the apparent metabolizable energy for poultry at all moisture levels at harvest of four varieties of corn. However, the adverse effects of elevated drying temperature are more evident when the moisture at corn harvest was 28 and 34%. Reductions of up to 96 and 126 kcal/kg are observed in those high moisture conditions at harvest when corn is dried at high temperatures (120 oC) instead of 35 oC.

Figure 1. Effect of corn varieties (A, B, C, D), moisture at harvest (%), and drying temperature (35, 120 oC) on apparent metabolizable energy (AME) for poultry (kcal/kg DM).

* The arrows indicate significant (P<0.001) effects of drying temperature on AME.

Nowadays, farmers have to harvest corn with high moisture due to summer storms that jeopardize their crops. These factors at harvest could increase variability in corn energy value. Nutritionists could identify the outcomes of these interactions at the feed mill using NIRS to evaluate corn batches and parameters like vitreousness and protein solubility index.

You may also like to read: “UNDERSTANDING CORN VARIABILITY: PART I”