Aflatoxicosis severity varies according to dose, exposure time, species, age, sexual cycle, nutritional status, etc.

19 Aug 2022

19 Aug 2022

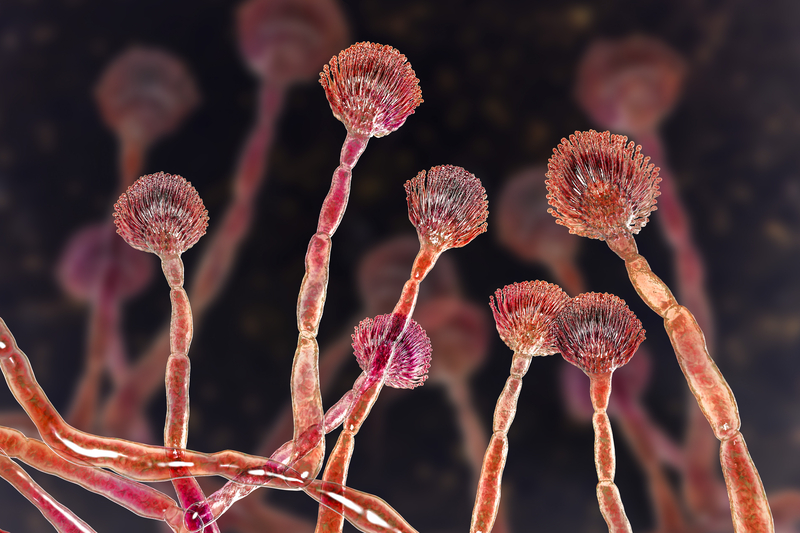

Aflatoxin contamination represents a food safety challenge for both animals and people. This type of contamination and its associated health hazards are referred to as Aflatoxicosis.

Aflatoxicosis severity varies according to dose, exposure time, species, age, sexual cycle, nutritional status, etc.

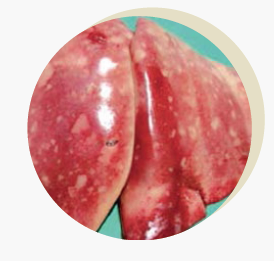

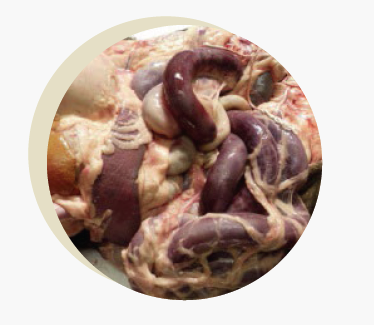

![]() The main target organs are the liver and kidney

The main target organs are the liver and kidney

Its main toxic and carcinogenic effects are:

The main clinical signs that occur are:

WHAT IS KNOWN ABOUT AFLATOXICOSIS IN DAIRY COWS?

The following points must be considered in order to assess present knowledge and what still remains undetermined.

Mechanisms of Aflatoxin Excretion in ruminants:

Carry over = Percentage of AFB1 excreted in milk as the metabolite AFM1.

This rate varies between 1-3% (min. 0.1% and max. 10%) and depends on:

These authors showed that cows with high somatic cell counts excrete more AFM1 in milk than cows with similar production levels but with lower somatic cell counts.

To counter in farm effects of AFB1 challenge and reduce the drag of AFM1 into milk, new feed additives (Mycotoxin Adsorbent Substances) must be used.

WHAT IS AN ADSORBENT AND WHAT FUNCTIONS SHOULD IT FULFILL?

EUROPEAN COMMISSION REGULATION (EC) No 386/2009, defines these additives as “reducers of feed contamination with mycotoxins: substances which may suppress or reduce absorption, promote excretion or modify mycotoxins’ action mechanism”.

An adsorbent must:

European regulation

This additive category is 1m558, specified in Implementing Regulation (EU) No 1060/2013.

The only mechanism recognised by the EU is the 1m558 group”category of technological additives. Functional group: reducers of feed contamination by mycotoxins: aflatoxin B1″.

This category specifies that Bentonite is the ONLY authorised adsorbent (EU). This bentonite must meet very specific and restrictive characteristics (other bentonites that do not meet the criteria are classified as additives 1m558i).

![]() POSITIVE ASPECTS

POSITIVE ASPECTS

![]() NEGATIVE ASPECTS

NEGATIVE ASPECTS

WHAT SHOULD BE DONE WHEN AFM1 IS DETECTED IN MILK?

Remove feed from milking cows and recycle it with heifers, in case it is not highly contaminated…

![]()

Carry out reliable SAMPLING with a quick response (ANALYSIS) in order to rapidly identify contaminated ingredient(s).

Quickly test corn and other suspicious ingredients with rapid tests (“immediate” response) and then confirm with HPLC (acetone).

![]()

Contaminated corn? Encourage contact between corn and adsorbing agent.

Screen, ventilate or clean the grain and/or reduce its inclusion with alternative ingredients (wheat, barley and sorghum).

Analyze cotton, soybeans and corn mix and silo (acetone+HPLC)

Contaminated cotton? Eliminate.

Contaminated corn silo or mix? Promote contact between adsorbent and feed and / or reduce its use with other alternatives (Grass silo, cereal silo, etc.)

Add 100-150g (or as indicated by technicians) of a guaranteed adsorbent(well chosen). Avoid overdosing.

If possible, put the contaminated feed in contact with the adsorbing agent.

Wait for 1-4 milkings (this will depend on the initial contamination levels).

Subscribe now to the technical magazine of animal nutrition

AUTHORS

Hybrid Rye Potential in Laying Hen Feed Rations

Gwendolyn Jones

A day in the life of phosphorus in pigs: Part I

Rafael Duran Giménez-Rico

Use of enzymes in diets for ruminants

Braulio de la Calle Campos

Minerals and Hoof Health in the Pregnant Sow

Juan Gabriel Espino

Impact of Oxidized Fats on Swine Reproduction and Offspring

Maria Alejandra Perez Alvarado