01 Nov 2022

01 Nov 2022

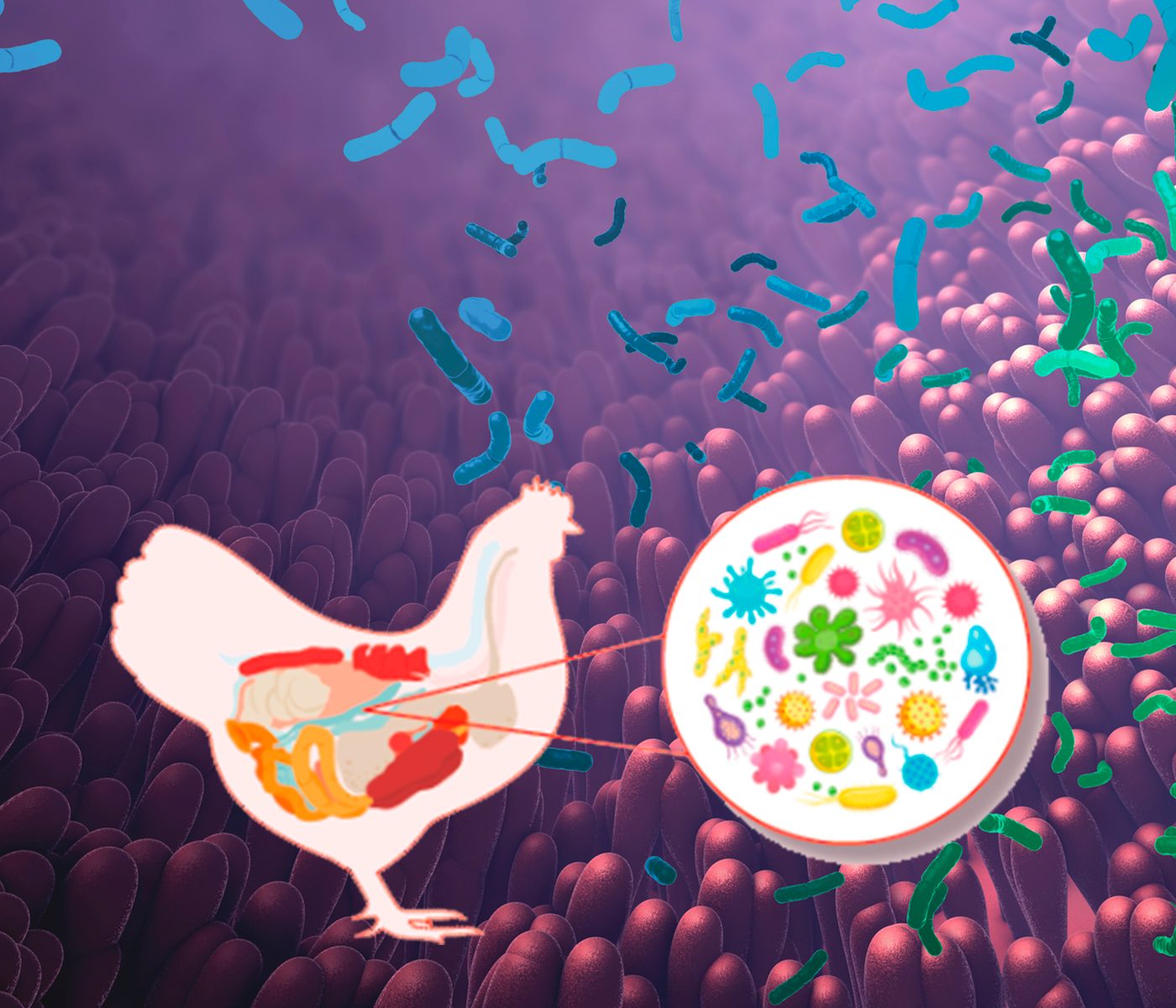

Gastrointestinal tract microbiota develops as soon as chicks hatch and become exposed to the external environment.

Besides the environmental, chemical and biological challenges posed by

modern intensive production systems, the first feed which is offered to chicks already contains a natural microbial community. This microbial community can be colonized with pathogens during feed processing and transport.

modern intensive production systems, the first feed which is offered to chicks already contains a natural microbial community. This microbial community can be colonized with pathogens during feed processing and transport.

In addition to pathogens, feed can also contain mycotoxins, heavy metals, pesticides, herbicides and other toxic contaminants.

Many of these feed contaminants have anomalous effects on the microbiota of adult birds, and these adverse effects are likely to be amplified in naïve birds.

On the other hand there is not enough literature regarding the effects of other contaminants like: radiation, chemical, industrial and toxic waste on the intestinal microbiota of birds.

The first bacteria to settle in the gut can attach to epithelial cells without competition. These are able to quickly establish themselves, grow, and modulate the intestinal environment to meet their needs.

Early bacterial colonists have the most important influence on the development of the host’s immune system and overall ability to thrive.

While gut microbial communities take around two years to mature in humans, the time period to maturity in poultry, is significantly reduced.

| Studies report that birds’ microbiota stabilizes greatly by the third day. |

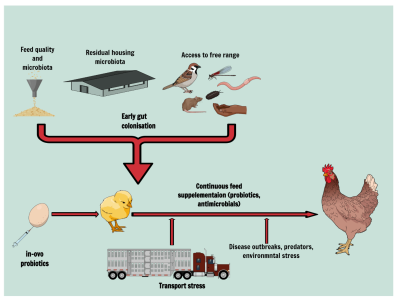

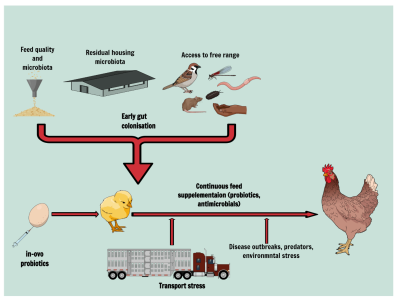

The critical process of intestinal colonization in the absence of maternal microbial inoculum of birds occurs through bacteria found in the natural microbiota of food as well as bacteria from the environment, including the litter and open field.

Range of factors that influence the colonization and maturation of the microbiota. (Image created with Mindthegraph).

![]() Microbial Contamination

Microbial Contamination

Adequate biosecurity measures are critical for early post-hatching feeding. considering the fact that early access of pathogens to the virgin gut can lead to mortality, lifelong colonization and permanent elimination of pathogens.

It is unreasonable to expect animal feed raw materials to be sterile. Granulation of finished feed converts crushed feed into dense granules, which reduces dust, and food waste. However, it does not eliminate microbes from feed.

The process involves the application of steam and pressure similar to a basic sterilization process in an autoclave. However, the duration of steam treatment is much shorter (from seconds to ~4 minutes of total heating time)in order to preserve the nutrients. Temperature is also less severe (65–78 °C) with a recommended pressure of 241–276 kPa.

Therefore, the granulation process helps with disinfection yet it does not sterilize the feed material. As it contributes to reducing the microbial load of finished feed, but it does not eliminate it entirely.

![]() Salmonella

Salmonella

Studies show that feed and factories are a major source of Salmonella contamination in the poultry industry.

Data regarding feeding and Salmonella in birds differs between studies and countries.

Gosling et al. summarized the literature on the widespread contamination of feed mills with Salmonella. They concluded that ingredient inlet wells were Salmonella hotspots which extended to all stages of growth, shipping, processing, storage, and finished feed.

These authors suggested the use of less toxic organic acids for the decontamination of Salmonella and E. coli instead of the widely used formaldehyde-based treatments.

[register]

![]() Clostridium perfringens

Clostridium perfringens

Toxin-producing C. perfringens is one of the main sources of serious intestinal disease in both animals and humans.

This common poultry pathogen causes significant economic losses to farmers. Colonization of birds with C. perfringens is an early event.

Contamination can spread to the farm environment and equipment. Including: fans, fly strips, dirt at the shed entrance, as well as the boots of farm personnel.

![]() E.coli

E.coli

E. coli is a common inhabitant of the gut microbiota in all species and most of its members are non-pathogenic.

E. coli is a common inhabitant of the gut microbiota in all species and most of its members are non-pathogenic.

However, those that are pathogenic are responsible for significant poultry mortality worldwide and represent a an ongoing production problem in both layers and broilers.

![]() Mycotoxins

Mycotoxins

Mycotoxins are secondary metabolites of filamentous fungi responsible for massive losses in agriculture worldwide.

Aflatoxins, ochratoxin A, deoxynivalenol patulin, fumonisins, zearalenone, trichothecenes, fumonisins and ergot alkaloids are considered to be the most significant in regards to food safety.

![]()

In addition, the range of fungal species that produce these toxins is quite broad. Including species like: Fusarium, Aspergillus, Penicillium and Claviceps.

Mycotoxins are carcinogenic, mutagenic, teratogenic, cytotoxic, neurotoxic, nephrotoxic, estrogenic and immunosuppressive. These tend to negatively affect the gut microbiota by increasing the abundance of pathogens and reducing or eliminating beneficial bacteria.

![]() Heavy metals

Heavy metals

The maximum permitted concentrations of heavy metals in livestock feed are recognized as a public health problem and are strictly regulated in countries around the world.

Heavy metal testing in feed is often performed in conjunction with mycotoxin testing. Heavy metal pollution differs from country to country and depends on heavy metal contamination levels.

Because of fish’s ability to concentrate heavy metals from contaminated waters, concentrations of heavy metals in fishmeal are of concern, especially in fish collected in the vicinity of or downstream from industrial waste disposal sites.

Some heavy metals also accumulate in the black soldier fly.

Heavy metals are known for:

From the intestinal microbiota establishment standpoint, the feed which is offered to offspring during the first days of microbiota formation must be immaculate regarding the presence of biological and chemical contaminants. It should also be enriched with beneficial microorganisms and pathogen-free. With a nutritional composition that includes fiber and favors other prebiotic-loving bacteria.

Source: Abstract taken from Stanley, Dragana, and Yadav Sharma Bajagai. 2022. “Feed Safety and the Development of Poultry Intestinal Microbiota” Animals 12, no. 20: 2890.

[/register]

Subscribe now to the technical magazine of animal nutrition

AUTHORS

Nutritional Interventions to Improve Fertility in Male Broiler Breeders

Edgar Oviedo

The Use of Organic Acids in Poultry: A Natural Path to Health and Productivity

M. Naeem

Synergistic Benefits of Prebiotics and Probiotics in Poultry, Swine, and Cattle

Gustavo Adolfo Quintana-Ospina

Hybrid Rye Potential in Laying Hen Feed Rations

Gwendolyn Jones

A day in the life of phosphorus in pigs: Part I

Rafael Duran Giménez-Rico

Use of enzymes in diets for ruminants

Braulio de la Calle Campos

Minerals and Hoof Health in the Pregnant Sow

Juan Gabriel Espino

Impact of Oxidized Fats on Swine Reproduction and Offspring

Maria Alejandra Perez Alvarado