03 Aug 2022

03 Aug 2022

Mycotoxin contamination in meat, and meat derived products represents a significant threat to food security and is a pressing matter that requires solutions.

There are several microbial groups capable of developing in meat and meat products, due to their ubiquity and tolerance to various environmental conditions.

Mycotoxins are secondary metabolites produced by molds that adversely affect the health of animals. They are a heterogeneous group, which translates into a great variability of toxic effects. Mycotoxins are produced by various species of molds, most of them being framed in the genera Aspergillus, Penicillium, Claviceps and Fusarium.

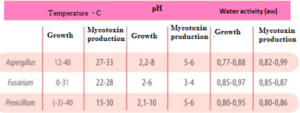

Microbial growth factors in meat and meat products

The factors that determine what type of microorganism proliferates in meat and meat products are determined by the physico-chemical characteristics of food, such as:

Bacteria are predominant in foods with elevated aw (>0.90)

Molds and yeasts constitute the major population in foods with lower aw values. such as cured-matured meat derivatives.

Although mold development does not always imply mycotoxin production, as such conditions tend to be more demanding (Table 1).

How can mycotoxins reach meat?

Mycotoxins can reach meat and its by-products in two ways:

Mycotoxin contamination from animal feed

In the case of mycotoxin contamination from animal feed, molds can produce toxins during the storage of cereals, food or silage due to storage conditions with low aw and good nutrient availability. as a result, it is within this environment where molds develop with greater ease.

Mycotoxin effects on animals can be very varied. Ranging from: causing mortality due to acute poisoning, or the onset of subclinical mycotoxicosis derived from long term consumption of mycotoxins at low doses.

In addition to this, mycotoxins ingested by animals can accumulate in different organs and tissues. This in turn poses a great danger for consumers, as mycotoxins are not destroyed with regular cooking treatments.

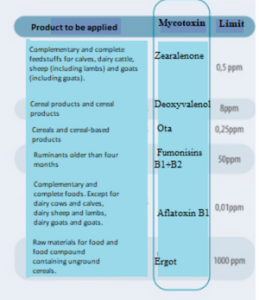

Regulation 574/2011 (European Commission, 2011) sets the maximum level of Aflatoxin B1 and ergot, producer of ergotamine (European Commission, 2011)

Recommendation 2006/576 (European Commission, 2006b) establishes the maximum indicative values that should not exceed the mycotoxins Ochratoxin A, Deoxynivalenol, Zearalenone, and Fumonisins B1 and B2 in foods with a moisture content of 12% (Table 2).

Table 2. Guideline values in mg/kg (ppm) for food with a moisture content of 12% (Recommendation 2006/576/EC and Regulation 574/2011/EC)

Due to the ubiquity of molds, effective controls to lower the risks of mycotoxins contamination in food and silage must be established for storage. Setting environmental conditions that prevent the development of molds and their subsequent mycotoxin production.

Development of molds on the surface of cured-matured meat derivatives

Molds that develop in cured-matured meat derivatives during maturation can have both positive and negative effects in relation to the quality and safety of the final product.

Benefits

They contribute to the proteolytic and lipolytic changes that occur during maturation.

They constitute an antioxidant barrier due to their production of enzymes such as catalase.

Disadvantages

Problems associated with mold growth on the ham surface have been described.

In recent years there has been a gradual increase in the legal regulations of the European Union setting the maximum content of these contaminants in food. Limits have been set for:

(*) In addition, in some countries such as Italy, the maximum permitted level of Ochratoxin A for pork and pork products has been set at 1 ppm (Ministerio della Sanità 1999)

Most of the molds isolated from sausages and cured ham belong to the genera Penicillium and Aspergillus, and are potentially toxigenic (Núñez et al. 1996). In addition, several toxigenic species belonging to these two genera produce mycotoxins when they develop on the surface of cured ham (Núñez et al. 2007; Rodríguez et al. 2012).

Mold control methods in cured-matured meat derivatives

Due to the risks posed by mycotoxins, it is necessary to establish viable strategies to avoid their synthesis during the processing of cured-matured meat derivatives.

There are different procedures to control such danger, such as:

Disadvantages of these methods:

Although various chemical preservatives such as sorbic acid and propionic acid can be used to control mold development, these are not fully effective. |

Given the not total efficacy and due to the growing demand for additive-free foods, it is necessary to use other alternatives to control the development of toxigenic molds during the maturation of food that avoids the use of these chemical preservatives.

Variations in the ripening conditions of these products could prevent the development of the fungal population, but may impair the sensory quality of the final product.

The industry has to look for alternative strategies to control this threat

One of the possibilities with the best prospects is based on the use of cultures of non-toxigenic strains that contribute to the maturation of the product where they are inoculated.

The ability of these microorganisms to implant and exert their effect will be better if they are strains isolated from cured-matured products, given their suitability to those particular ecological conditions.

The use of these microorganisms as protective cultures does not imply a break with the usual microbiota in these products.

Among the microorganisms present in this type of products that can slow down the development of toxigenic molds or the formation of mycotoxins, lactic acid bacteria, yeasts and molds that produce antifungal proteins stand out.

This work has been funded by the Ministry of Economy and Competitiveness, Junta de Extremadura and FEDER (AGL2013-45729-P, GR15108).

[/register]

Subscribe now to the technical magazine of animal nutrition

AUTHORS

Nutritional Interventions to Improve Fertility in Male Broiler Breeders

Edgar Oviedo

The Use of Organic Acids in Poultry: A Natural Path to Health and Productivity

M. Naeem

Synergistic Benefits of Prebiotics and Probiotics in Poultry, Swine, and Cattle

Gustavo Adolfo Quintana-Ospina

Hybrid Rye Potential in Laying Hen Feed Rations

Gwendolyn Jones

A day in the life of phosphorus in pigs: Part I

Rafael Duran Giménez-Rico

Use of enzymes in diets for ruminants

Braulio de la Calle Campos

Minerals and Hoof Health in the Pregnant Sow

Juan Gabriel Espino

Impact of Oxidized Fats on Swine Reproduction and Offspring

Maria Alejandra Perez Alvarado