Mycotoxins are secondary metabolites generated by fungi and molds that infest plants and their products during both the vegetative phase and storage.

![]() The composition and quantity of mycotoxins produced can vary depending on fungal growth under specific environmental conditions, such as humidity and temperature.

The composition and quantity of mycotoxins produced can vary depending on fungal growth under specific environmental conditions, such as humidity and temperature.

![]() The presence of mycotoxins in animal feed not only poses risks to animal health and productivity but also potentially contaminating the food chain, thereby impacting human health.

The presence of mycotoxins in animal feed not only poses risks to animal health and productivity but also potentially contaminating the food chain, thereby impacting human health.

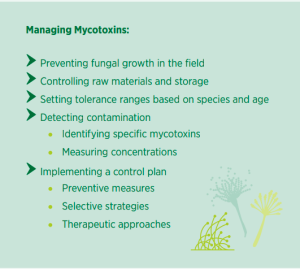

![]() To control mycotoxins, it is crucial to prevent the proliferation of toxin-producing microorganisms.This can be achieved through:

To control mycotoxins, it is crucial to prevent the proliferation of toxin-producing microorganisms.This can be achieved through:

![]() The implementation of Good Agricultural Practices

The implementation of Good Agricultural Practices

![]() The use of antifungal agents in crops

The use of antifungal agents in crops

![]() Control during processing, storage, and transportation of grains, ensuring proper drying, especially for corn. Avoiding high levels of moisture and temperature in transportation and silos.

Control during processing, storage, and transportation of grains, ensuring proper drying, especially for corn. Avoiding high levels of moisture and temperature in transportation and silos.

However, zero risk does not exist, and a cereal that has been harvested under optimal conditions can be transported thousands of kilometers and stored under different conditions that favor fungal growth and, therefore, mycotoxin production.

Regarding the risk level, one difference lies in the type of fungus or mycotoxin found:

![]() While the presence of Fusarium spp. in the field leads to contamination with mycotoxins such as zearalenone, trichothecenes, and fumonisins, it is during storage that the growth of Aspergillus spp. and Penicillium spp., which cause contamination by aflatoxins and ochratoxin, is more common.

While the presence of Fusarium spp. in the field leads to contamination with mycotoxins such as zearalenone, trichothecenes, and fumonisins, it is during storage that the growth of Aspergillus spp. and Penicillium spp., which cause contamination by aflatoxins and ochratoxin, is more common.

The market offers a variety of products with the capacity to retain or inactivate mycotoxins present in feed, thus reducing or preventing their entry into the animal’s body.

However, due to the diverse molecular structures of mycotoxins, finding effective products with broad-spectrum activity is challenging. Although a dozen mycotoxins are recognized as posing higher potential risks, the sheer number of distinct mycotoxins complicates the selection of suitable products.

However, due to the diverse molecular structures of mycotoxins, finding effective products with broad-spectrum activity is challenging. Although a dozen mycotoxins are recognized as posing higher potential risks, the sheer number of distinct mycotoxins complicates the selection of suitable products.

Choosing an appropriate product is complicated since the threat is ever-present, and even with good control of some mycotoxins, contamination is often multifactorial.

Choosing an appropriate product is complicated since the threat is ever-present, and even with good control of some mycotoxins, contamination is often multifactorial.

Mycotoxin contamination is not consistently present, nor does it exhibit uniform intensity. Hence, it is crucial to maintain control measures throughout the entire supply chain, from raw material sourcing and reception to storage. Employing monitoring systems and rapid detection methods for suspicious batches is essential.

![]() The implementation of effective control measures before feed production allows for corrective actions such as selecting appropriate species and production periods and utilizing products that can neutralize specific mycotoxins present in a given batch of feed.

The implementation of effective control measures before feed production allows for corrective actions such as selecting appropriate species and production periods and utilizing products that can neutralize specific mycotoxins present in a given batch of feed.

For example, the use of DON-contaminated cereal will have different effects on piglet feed compared to finishing feed. Similarly, the presence of fumonisins affects poultry more significantly than cattle.

In the event of contaminated feed reaching the farm, it is difficult to establish an accurate diagnosis as the clinical signs can be diverse and often similar to other pathologies.

After the confirmation through analytical testing of the feed, the possibilities for inactivating mycotoxins are restricted, and only prompt and efficient measures can be implemented to facilitate their elimination and mitigate the impact on organs like the liver, kidney, gastrointestinal tract, lungs, and more.

When utilized in drinking water, these products operate synergistically by combining botanical extracts with detoxifying properties, mycotoxin-inactivating compounds, and essential vitamins and provitamins.

When utilized in drinking water, these products operate synergistically by combining botanical extracts with detoxifying properties, mycotoxin-inactivating compounds, and essential vitamins and provitamins.

Understanding the extent and nature of the contamination we are encountering

Understanding the degree and type of contamination we are facing is crucial. The real impact of mycotoxins is primarily determined by the level of contamination. Recent studies have shown an increase in mycotoxin contamination in analyzed samples, reaching values higher than 70%.

![]()

Once their presence is identified, it is necessary to analyze the specific types of mycotoxins and the level of contamination.

For the most prevalent aflatoxin contamination, feed limits (as per Directive 2002/32/EC) are set between 10-20 ppb, except for dairy cattle due to the potential impact on the food chain, where it is reduced to 5 ppb.

The recommendations for monogastric animals, mainly for the remaining mycotoxins, could be established within a range of values:

![]() Ochratoxin 50-100 ppb

Ochratoxin 50-100 ppb

![]() Zearalenone 100-250 ppb

Zearalenone 100-250 ppb

![]() DON 500-2000 ppb

DON 500-2000 ppb

![]() T-2 200 ppb

T-2 200 ppb

![]() Fumonisin 1000-5000 ppb

Fumonisin 1000-5000 ppb

For early stages or during breeding, the recommended values are at their lowest, whereas for the fattening phase, the recommended values reach their maximum.

![]() In the case of ruminants, there is controversy regarding the detoxifying capacity of the rumen flora for some mycotoxins (ochratoxin and fumonisin) and how they may or may not affect the animal.

In the case of ruminants, there is controversy regarding the detoxifying capacity of the rumen flora for some mycotoxins (ochratoxin and fumonisin) and how they may or may not affect the animal.

![]() Regardless, if the levels of Zearalenone, DON, and T-2 exceed the recommended values for monogastric animals, they would also exceed the recommendation for ruminants.

Regardless, if the levels of Zearalenone, DON, and T-2 exceed the recommended values for monogastric animals, they would also exceed the recommendation for ruminants.

Based on recent studies (Global Mycotoxin Occurrence in Feed: A Ten-Year Survey, Gruber-Dorninger, C.; Jenkins, T.; Schatzm G., Published: 27 June 2019 www.mdpi.com), it has been found that in both feed and raw materials, the presence of two or more mycotoxins is common.

Storage conditions often lead to cereals in tropical regions having high levels of aflatoxin contamination and low levels of ochratoxin. However, the combined presence of both mycotoxins intensifies the negative effect, surpassing the cumulative impact of each individual toxin.

Control mechanisms

The goals of addressing the effects of mycotoxins include:

1- Reducing their presence and bioavailability through the use of adsorbent or biotransforming agents.

2- Strengthening the animal’s control mechanisms, including intestinal absorption and hepatic detoxification processes, when the previous approach is insufficient.

![]() Ensuring that ingredients used in the feed plant are easily manageable, with good flowability and dispersion, and remain stable during storage and extrusion/pelletizing processes.

Ensuring that ingredients used in the feed plant are easily manageable, with good flowability and dispersion, and remain stable during storage and extrusion/pelletizing processes.

![]() Avoiding interference with other nutrients, such as vitamins, minerals, or pharmaceuticals.

Avoiding interference with other nutrients, such as vitamins, minerals, or pharmaceuticals.

![]() They should have a broad spectrum of action against mycotoxins.

They should have a broad spectrum of action against mycotoxins.

![]() Their effect should be stable under pH changes.

Their effect should be stable under pH changes.

![]() They should be biodegradable or inert to the environment.

They should be biodegradable or inert to the environment.

Within the array of products utilized to counteract mycotoxins and their impacts, a range of options is available.

Mineral adsorbents: The adsorption capacity of these adsorbents depends on their structure, composition, charge, and the polarity of the mycotoxin. Clay minerals, such as bentonites, zeolites, and sepiolites, are examples of natural or physically modified aluminosilicates. They possess good adsorption capacity and low desorption rates, particularly for more polar mycotoxins like aflatoxin, ochratoxin, zearalenone, T-2, and fumonisin.

Mineral adsorbents: The adsorption capacity of these adsorbents depends on their structure, composition, charge, and the polarity of the mycotoxin. Clay minerals, such as bentonites, zeolites, and sepiolites, are examples of natural or physically modified aluminosilicates. They possess good adsorption capacity and low desorption rates, particularly for more polar mycotoxins like aflatoxin, ochratoxin, zearalenone, T-2, and fumonisin.

Biological adsorbents: These include yeast cell walls that have been modified to effectively bind and remove various mycotoxins such as ochratoxin and zearalenone. Additionally, they have the ability to provide immune-stimulating substances.

Biological adsorbents: These include yeast cell walls that have been modified to effectively bind and remove various mycotoxins such as ochratoxin and zearalenone. Additionally, they have the ability to provide immune-stimulating substances.

Bio-transformers: These are typically microorganisms or enzymes that can transform the chemical structure of mycotoxins into metabolites that are less toxic.

Bio-transformers: These are typically microorganisms or enzymes that can transform the chemical structure of mycotoxins into metabolites that are less toxic.

![]() They are highly specific products, such as oxidases, catalases, lactonases, and esterases, and their effectiveness can vary depending on the pH conditions in the environment. To maximize their efficacy, it is recommended to use combinations of these bio-transformers.

They are highly specific products, such as oxidases, catalases, lactonases, and esterases, and their effectiveness can vary depending on the pH conditions in the environment. To maximize their efficacy, it is recommended to use combinations of these bio-transformers.

Bio-protectors and repairing compounds:These substances comprise organic acids, probiotics, prebiotics, and botanical extracts, all of which are instrumental in protecting and repairing the intestinal mucosa from the harmful effects of mycotoxins, specifically trichothecenes. They work by reducing the absorption of mycotoxins into the bloodstream and other target organs.

Bio-protectors and repairing compounds:These substances comprise organic acids, probiotics, prebiotics, and botanical extracts, all of which are instrumental in protecting and repairing the intestinal mucosa from the harmful effects of mycotoxins, specifically trichothecenes. They work by reducing the absorption of mycotoxins into the bloodstream and other target organs.

Specific vitamins & provitamins:These essential nutrients, in combination with natural antioxidants and silymarin and cynarin extracts, actively support the hepatic-renal metabolism involved in detoxification processes.

Specific vitamins & provitamins:These essential nutrients, in combination with natural antioxidants and silymarin and cynarin extracts, actively support the hepatic-renal metabolism involved in detoxification processes.

In order to minimize the potential negative impact of mycotoxins, it is crucial to utilize binding agents that are customized to address the specific needs and risks involved. This strategic approach ensures a focused and comprehensive strategy in combating mycotoxins.

The FINTOX line of binding agents offers products tailored to the following needs:

![]() Adsorption

Adsorption

![]() Biotransformation

Biotransformation

![]() Bioprotection

Bioprotection

![]() Biorepair

Biorepair

The FINTOX range of binding agents harnesses the combined power of carefully selected ingredients:

![]() Aluminosilicates

Aluminosilicates

![]() Yeast cell walls and extracts

Yeast cell walls and extracts

![]() Organic acids and byproducts of microbial fermentation, enabling the irreversible adsorption and biotransformation of mycotoxins while preserving the integrity of other essential dietary nutrients

Organic acids and byproducts of microbial fermentation, enabling the irreversible adsorption and biotransformation of mycotoxins while preserving the integrity of other essential dietary nutrients

![]() Prebiotics, provitamins, and phytobiotics that safeguard vital organs against these hazardous substances and aid in the restoration of damaged tissues (such as the liver, kidney, intestine, and immune system).

Prebiotics, provitamins, and phytobiotics that safeguard vital organs against these hazardous substances and aid in the restoration of damaged tissues (such as the liver, kidney, intestine, and immune system).

Conclusions: